Where can tungsten-cobalt alloy bushings be used?

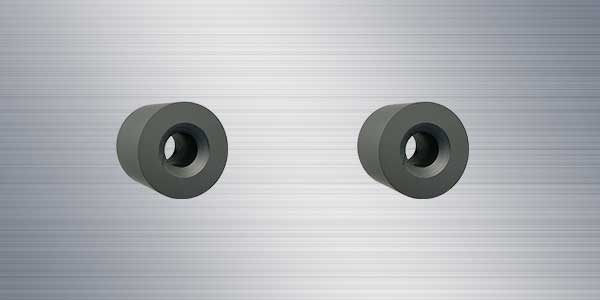

Tungsten-cobalt alloy bushing is a bush made of tungsten as the matrix and added metal cobalt. It is often called YG alloy product. Tungsten-cobalt alloy bushing is wear-resistant, corrosion-resistant, stamping-resistant, and has stable chemical and physical properties. Different fields of use have different performance requirements. Of course, the toughness and hardness of the bushing can be adjusted by adjusting the ratio of raw materials to meet different needs.

Tungsten carbide is the basic material in friction materials and is widely used as the basic component of seals. Carbide bushings are widely used in petrochemical industry due to their excellent properties such as wear resistance and corrosion resistance.

The tungsten-cobalt alloy bushing can also be used as a kind of sliding bearing, which can be freely rotated or moved on the shaft with high precision. It can work normally and orderly under harsh working conditions. It has excellent high temperature resistance, chemical resistance and strong impact resistance. It can be used for heavy loads, reducing wear between the bearing and the shaft seat, and avoiding the gap between the shaft and the hole. The gap between them increases.

Tungsten-cobalt alloy bushings are also widely used in valves. The bushings are installed on the valve stem and bonnet to avoid the loss of gas, liquid and other media in the valve for sealing.

The above are just some of the application fields of tungsten-cobalt alloy bushings, and the bushings with good performance meet the use requirements in harsh environments.