What is tungsten carbide strips used for?

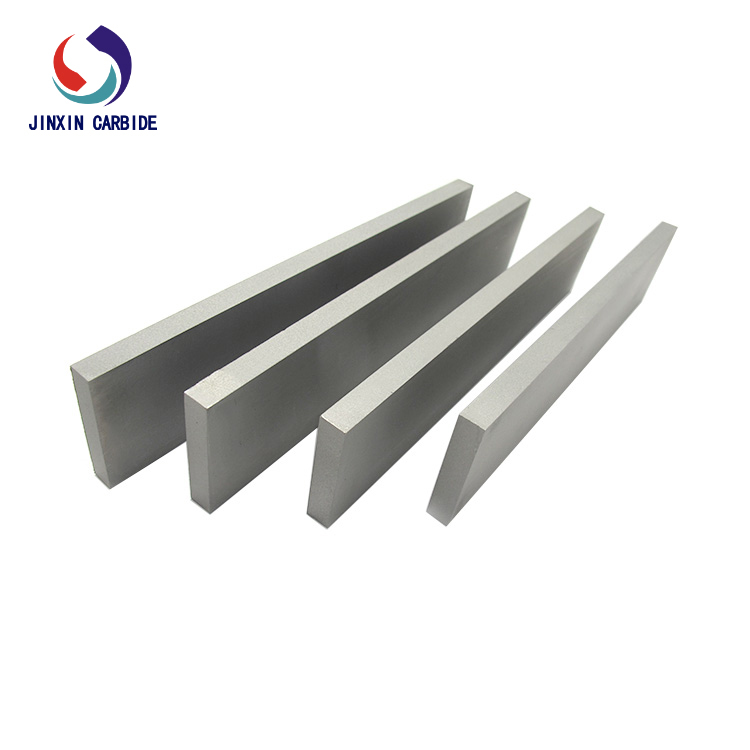

As a high-performance composite material, tungsten carbide strips are sintered from tungsten carbide particles and cobalt binders. With the characteristics of Rockwell hardness HRA ≥ 90 and bending strength ≥ 2500MPa, they have become the core material under extreme working conditions. Its grain size control technology (0.5-3μm) and composition optimization (WC content 80%-95%) make it play a key role in cutting tools, energy exploration, aerospace and other fields.

In mechanical manufacturing, tools made of tungsten carbide strips can process hard-to-cut materials such as hardened steel and titanium alloys, and their service life is 3-5 times longer than that of high-speed steel tools. In the field of energy exploration, the rock breaking efficiency of oil drill bits is increased by 30% after tungsten carbide teeth are embedded, and the life of coal mining machine picks is extended by more than 2 times.

In the field of aerospace, tungsten carbide and nickel-based alloy composite coatings are used for turbine engine blade mortise and tenon grooves, which can withstand high temperatures of 1000℃ and tens of thousands of revolutions of centrifugal force. In medical equipment, dental implant bases combined with tungsten carbide and titanium alloys have both high strength and biocompatibility. The semiconductor industry uses its super-hard properties to manufacture wafer cutting blades, while the environmental protection field uses it in acid-resistant pump impellers.