Do you know what should be paid attention to in the installation of cemented carbide rolls?

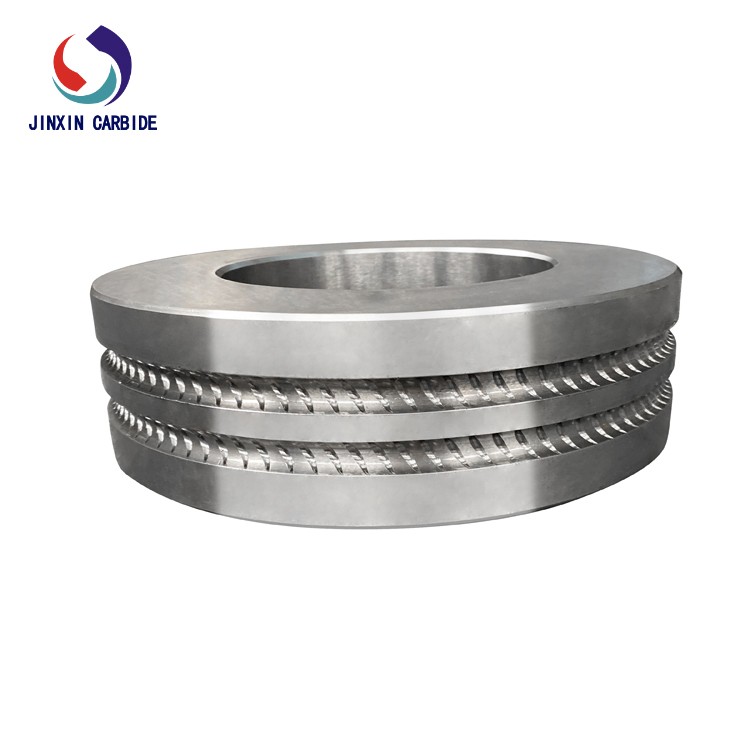

Carbide roll has good wear resistance, high temperature red hardness, heat resistance fatigue and high strength, has been widely used in the production of rod, wire, rebar and seamless steel tube, greatly improving the effective operating rate of the rolling mill.According to the difference of working environment of each frame roll, various grades of carbide roll rings have been developed.There are two kinds of cemented carbide rolls: integral type and combined type.Excellent performance, stable quality, high processing precision, good wear resistance and high impact resistance.In use, we need to pay attention to the following matters during the installation process:

1. Roller distribution: the difference between the same roller on the same frame should be 0, not more than plus or minus 0.05mm

2. Before loading the roller, the roller ring and cone sleeve should be kept warm at a constant temperature of 25-30 degrees Celsius. At the same time, the roller shaft should be poured with hot water, or it should be idled for 20 minutes to preheat.

3. Roller ring inserts and machine assembly should be carried out in strict accordance with the precision required by the design process. The proper fit between the roller ring and the roller shaft of the frame and the cone sleeve should not be too tight or too loose

4. Check whether the roller ring meets the requirements before loading the machine, and the assembly surface of the roller ring, cone sleeve and shaft should be carefully scrubbed clean. It is strictly forbidden to hit the roller ring with hammer or other hard objects when loading the machine, and it is strictly forbidden to collide with each other in the process of transportation and installation to prevent damage to the roller ring.

With the demand of economic development, many iron and steel enterprises in pursuit of development, constantly update their own equipment and technology at the same time, also constantly improve the rolling speed of rolling mill, reduce The Times of rolling mill downtime, and further improve the effective operating rate of rolling mill.The cemented carbide roll with longer rolling life is one of the important means to achieve the goal.Therefore, it is particularly important to choose a company that produces high-quality cemented carbide roller rings. Zhuzhou Jinxin is a one-stop cemented carbide production customization service provider, focusing on the research and development and production of high-quality cemented carbide materials, with a complete variety of molds, a large inventory of conventional products, and support for customized drawings and samples. The delivery time is fast and the supply capacity is strong.