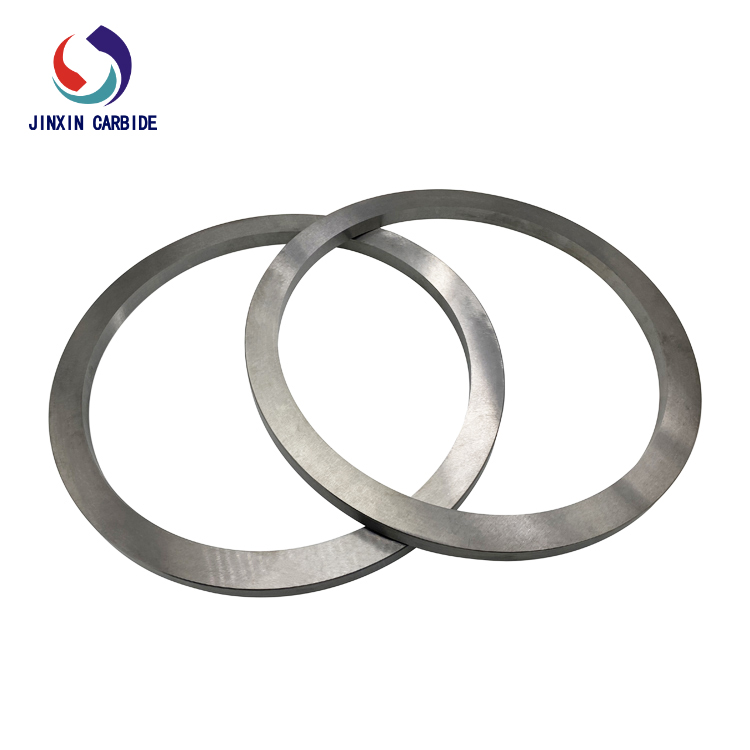

Common structural forms of carbide mechanical seals

Carbide mechanical seal ring is a commonly used sealing element and is widely used in various rotating

equipment and mechanical devices. They adopt different structural forms to adapt to different working

conditions and sealing requirements. This article will introduce several common structural forms of

carbide mechanical seals.

Double-end mechanical seal ring: The double-end mechanical seal ring consists of two sealing rings

and a spacer ring. The sealing rings are in contact with both sides of the rotating shaft. The spacer ring

is located between the two sealing rings to form a space. Through the action of pressure and lubricant

or sealant, double-end sealing rings can achieve effective sealing on both contact surfaces, providing

more reliable sealing performance.

Multi-layer mechanical seal ring: Multi-layer mechanical seal ring is a sealing form with complex

structure, consisting of multiple seal rings, spacer rings and compensation rings. Multi-layer mechanical

seals are usually used in high-pressure and high-temperature environments. They can withstand greater

pressure and temperature changes and provide a more stable sealing effect. Each sealing ring assumes

a different sealing function, forming a multi-layer sealing system.

Floating ring mechanical seal: The floating ring mechanical seal is a special structural form, which

includes a sealing ring and a floating ring. The sealing ring is in contact with the rotating shaft or

equipment housing, while the floating ring is set in the sealing ring and can float freely within a certain

range. The floating ring maintains the gap with the sealing ring through the action of pressure and

lubricant or sealant, reduces friction and wear, and improves sealing performance and service life.