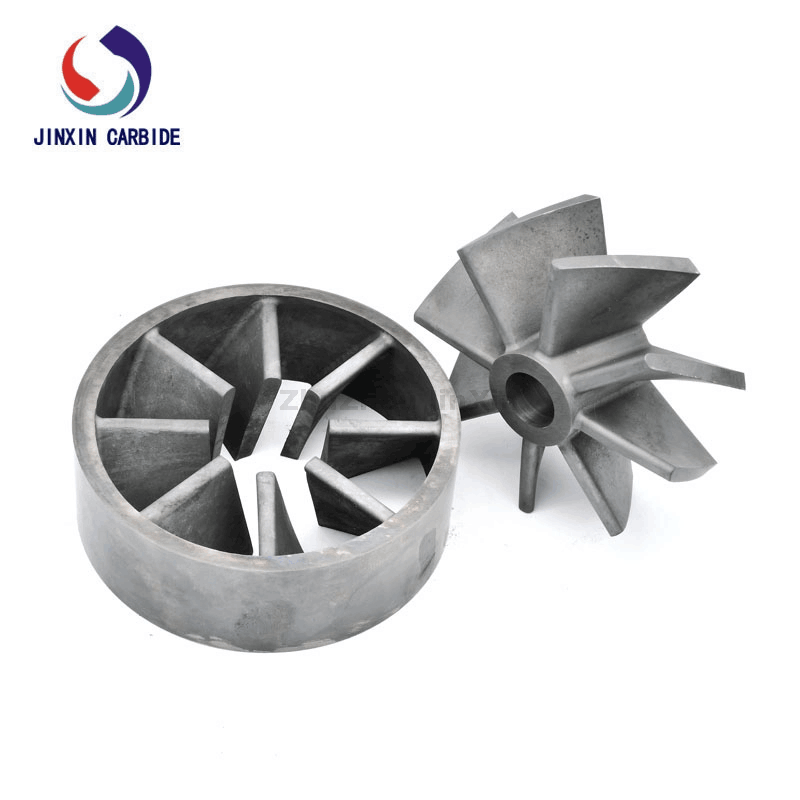

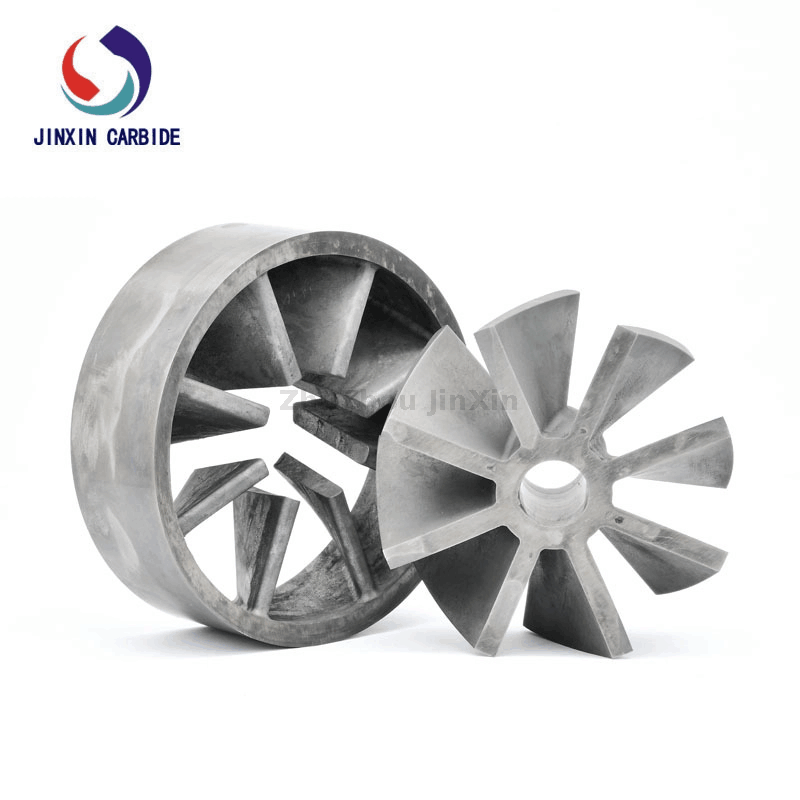

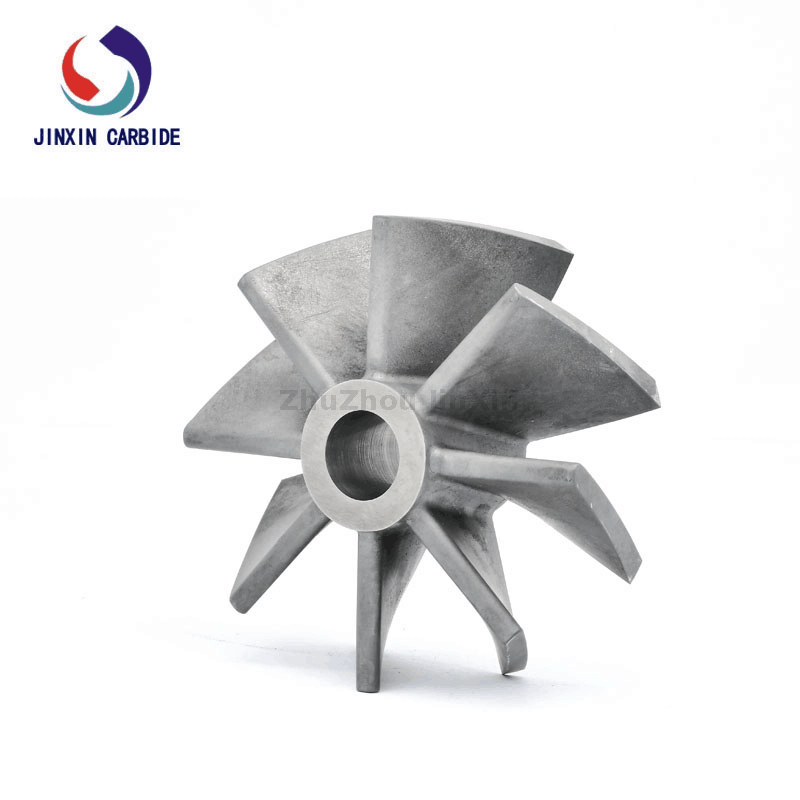

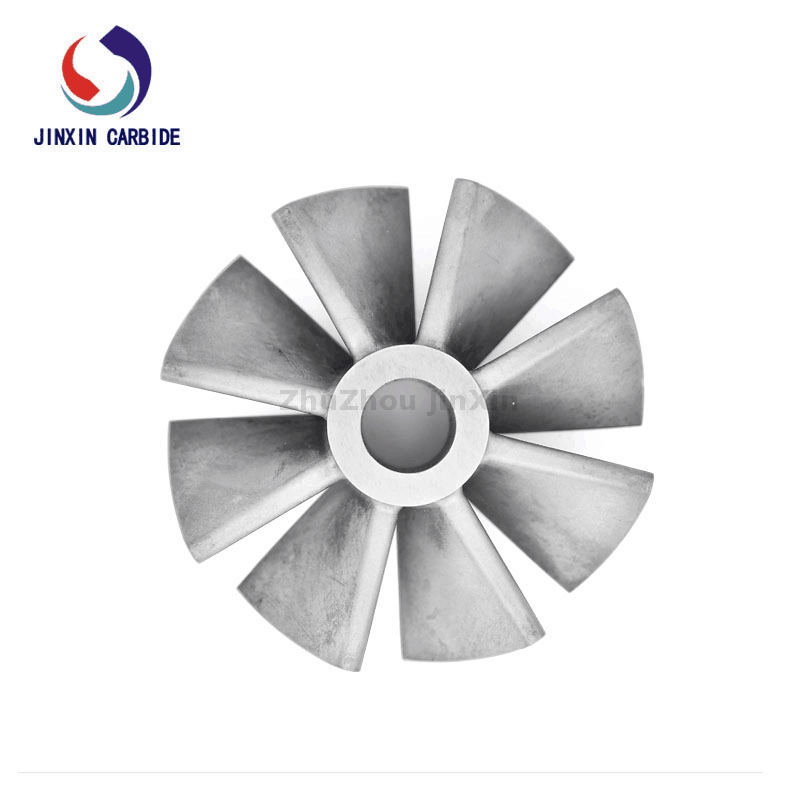

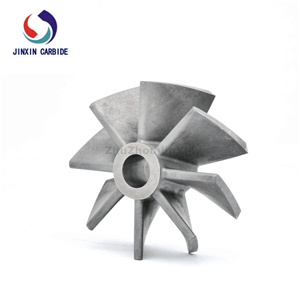

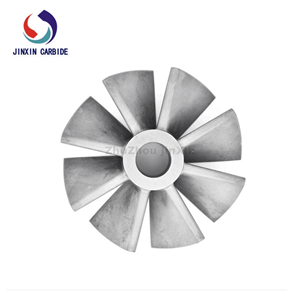

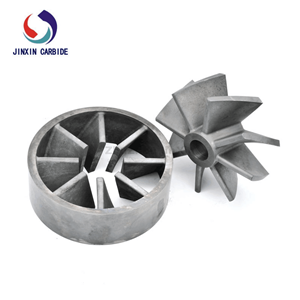

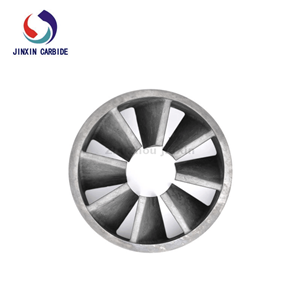

OEM/ODM Carbide Rotors and Stators

Brand Name : JINXIN

Place of Origin : China

MOQ : 5kg

Packaging Details : International standard transport requirements

Delivery Time : 15 days

Supply Ability : 1000000 PCS/MONTH

Matierial : Tungsten carbide with steel

Tungsten Carbide Stators (TCS) are widely used in the oil and gas industry, particularly in Measurement While Drilling (MWD) and Logging While Drilling (LWD) technologies. These stators provide critical structural support and protection for drilling equipment in high pressure, high wear environments.

Tungsten carbide stators for oil and gas industry

Designed specifically for the oil and gas industry, our tungsten carbide stators offer excellent wear and corrosion resistance for demanding applications such as MWD and LWD. With high strength, high temperature stability and customized designs, our stators ensure optimal performance and maximum life in demanding drilling environments.

Tungsten carbide stators feature

Superior Wear Resistance: The high hardness of the tungsten carbide allows the stator to perform well under high friction conditions, significantly extending service life.

HIGH STRENGTH AND TOUGHNESS: With high compressive strength and impact resistance, it is able to withstand high loads and impacts during the drilling process.

CORROSION RESISTANCE: Exhibits excellent corrosion resistance in harsh chemical environments, ensuring long term stable operation of the stator in corrosive fluids.

High-temperature stability: able to maintain stable performance in high-temperature environments, suitable for deep wells and high-temperature drilling operations.

Customized design: Different sizes and specifications of stator can be provided according to customers' needs to meet the requirements of various complex drilling conditions.