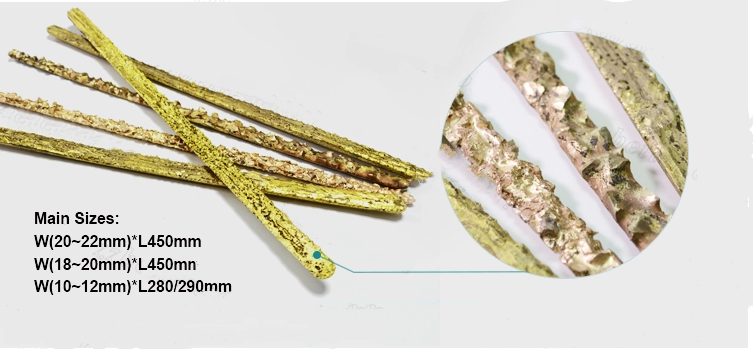

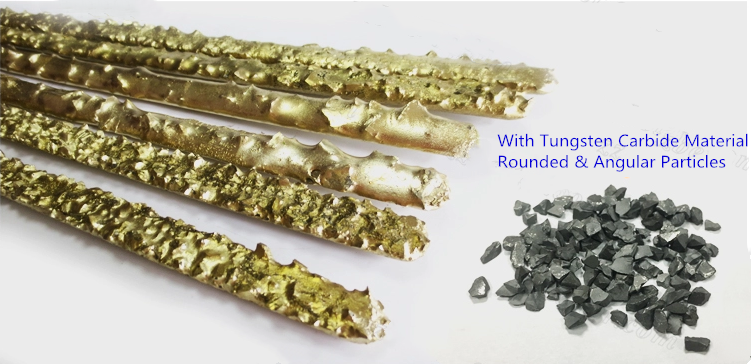

Tungsten carbide composite rods

Brand Name : JINXIN

Place of Origin : CHINA

Delivery Time : 7-14DAYS

Supply Ability : 1000TON/MONTH

1.With strict tolerance extent control 2.Enjoy excellent wear resistance & high toughness 3.Have very good thermal & chemical stability 4.Anti-deformation & deflection 5.A special Hot Isostatic Press (HIP) process provides quality improvement to the finished products to ensure material reliability. Welcome your inquiries. Also we can send you some samples for your testing.

Tungsten carbide composite welding rod description

Tungsten carbide composite rod, compositewelding rod, YD welding rod, is made of by sintering tungsten carbide scrap and elastic matrix alloy, Outer layer of the special flux and coloring is marking scrap grade, the composition of sintering tungsten carbide scrap is mainly CO and WC, The hardness is HRA 89~91, tire body matal is Ni and copper alloy, strength can up to 690 MPa, hardness HB≥160.

Tungsten Carbide Copper Composite Welding Rod Grade

| Grade | Chemical compositions ( ≦% ) | ||

| Cu+Zn+Sn | WC | Co | |

| Cu-40 | 40±2 | 53-56 | 4.6-4.8 |

| Cu-45 | 45±2 | 48-52 | 4.2-4.5 |

| Cu-50 | 50±2 | 44-48 | 3.8-4.2 |

Tungsten Carbide Ni-Cu Composite Welding Rod Grade

| Grade | Chemical compositions ( ≦% ) | ||

| Cu+Zn+Sn | WC | Co | |

| Ni-Cu 40 | 40±2 | 53-57 | 4.6-5.0 |

| Ni-Cu 45 | 45±2 | 49-52 | 4.2-4.5 |

| Ni-Cu 50 | 50±2 | 44-48 | 3.8-4.1 |

Tungsten Carbide YD Welding Rod Application

Tungsten Carbide YD welding rods are widely used in mining drilling, oil and gas, metallurgy, agriculture, building materials and other industries, mainly used to strengthen the wear resistance, impact resistance and corrosion resistance of the workpiece surface. Common applications include drill bits, crusher hammers, excavator teeth, metallurgical roller presses, agricultural knives, cement mixer liners, etc., which can effectively extend the service life of the equipment and improve work efficiency.