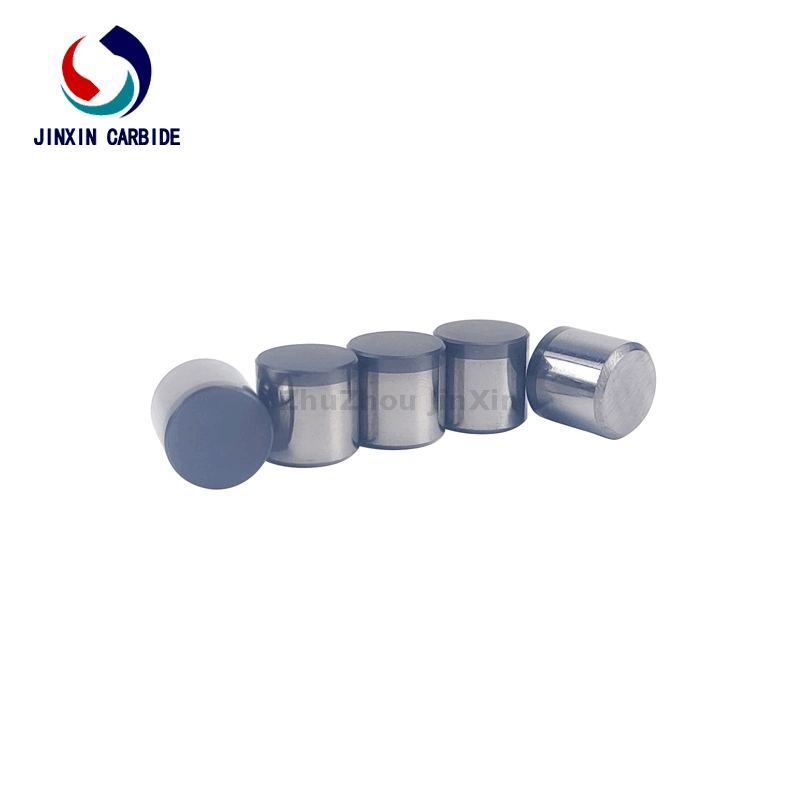

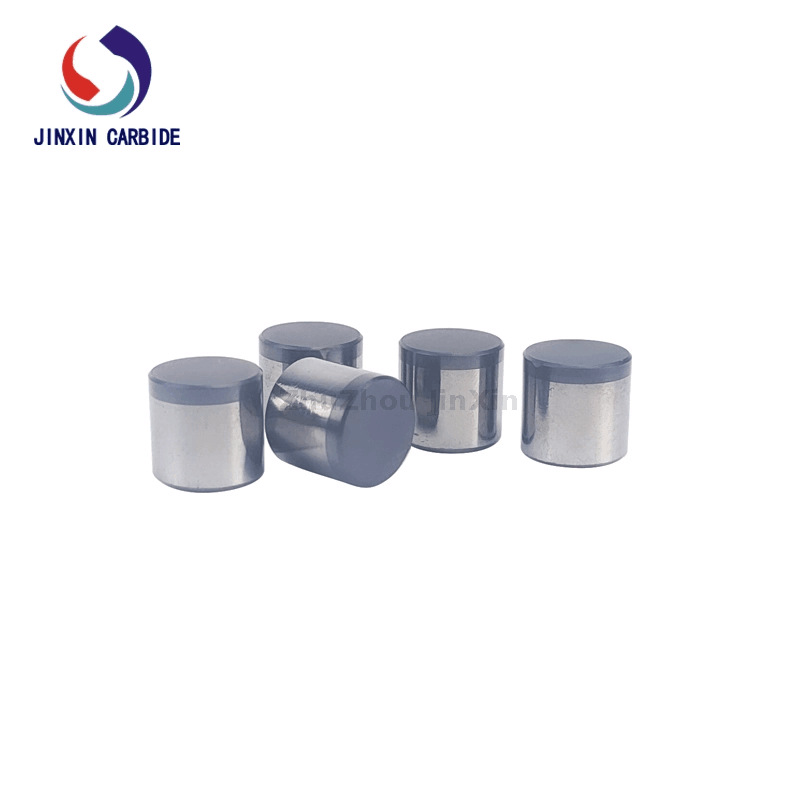

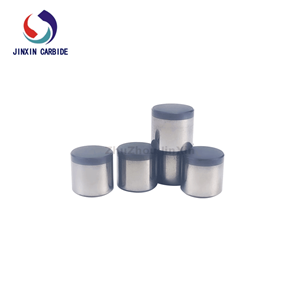

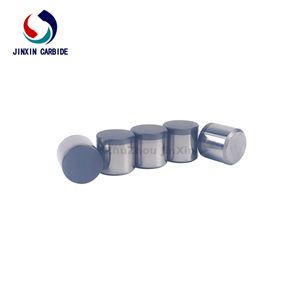

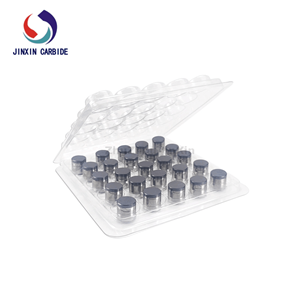

High wear-resistant PDC cutters for mining

Brand Name : JINXIN

Place of Origin : China

MOQ : 5kg

Packaging Details : International standard transport requirements

Delivery Time : 15 days

Supply Ability : 1000000 PCS/MONTH

Matierial : Tungsten carbide with steel

Due to the high toughness provided by the cemented carbide matrix, the flexural strength of PDC inserts is up to 1500MPa, which can withstand high impact loads.

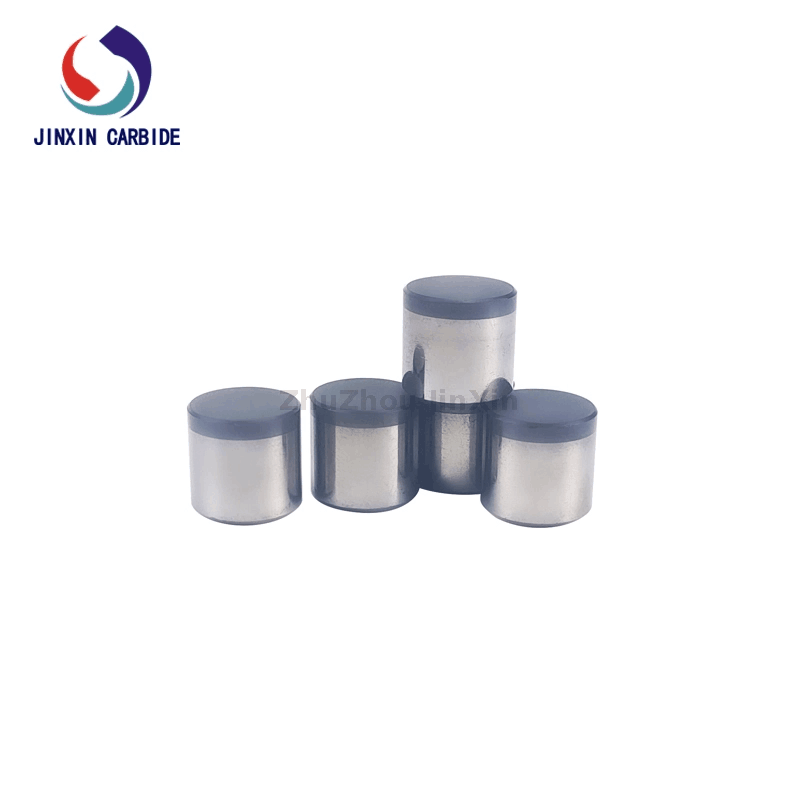

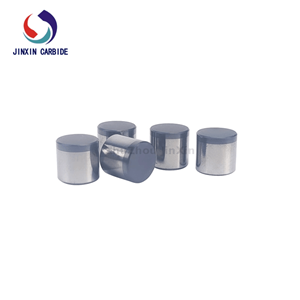

Carbide PDC cutter / insert description

Carbide PDC inserts (Polycrystalline Diamond Compact) is a composite material consisting of a polycrystalline diamond layer and a cemented carbide matrix, which is widely used in oil and gas drilling as well as mining.

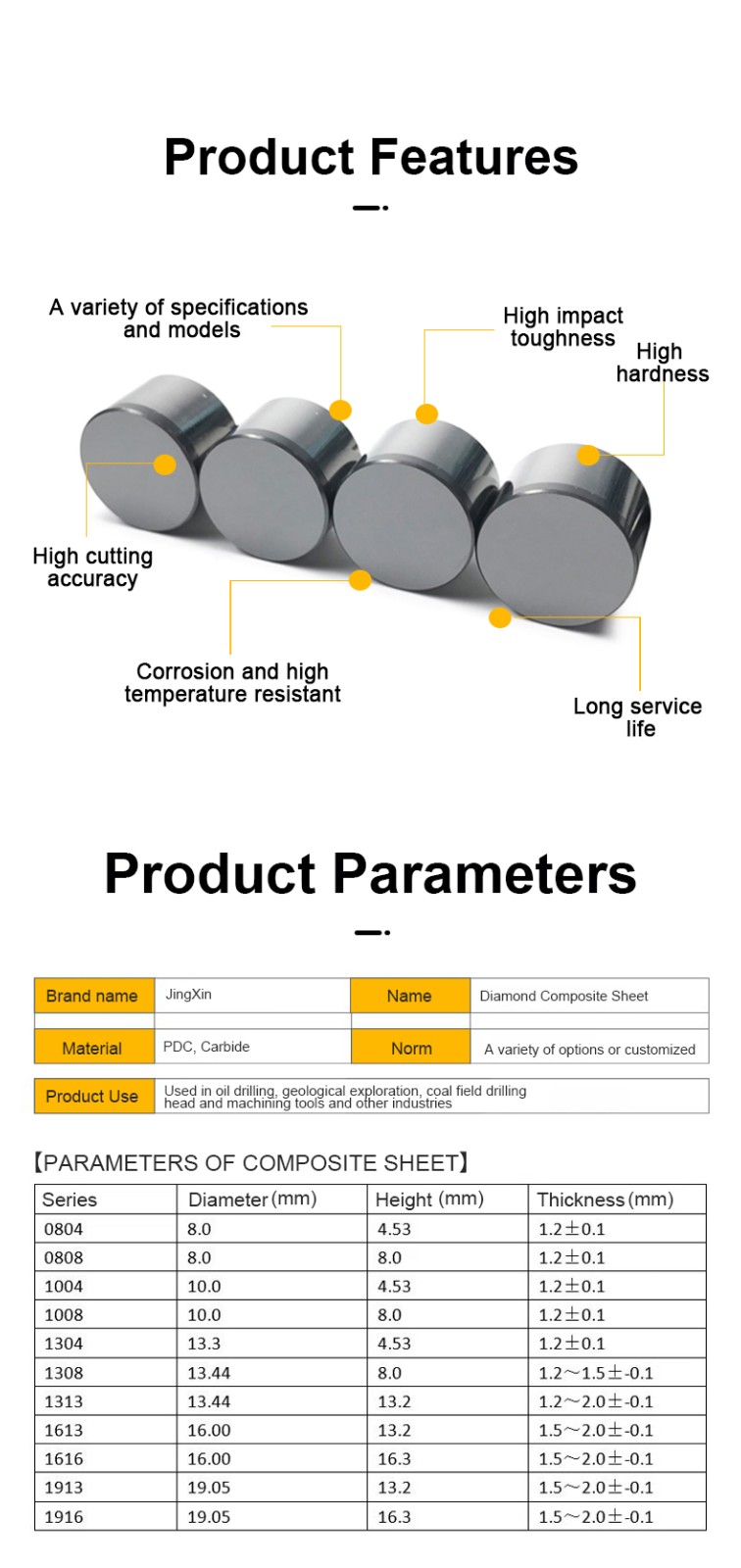

Carbide PDC cutter / insert features

The hardness of polycrystalline diamond layer reaches HV7500~9000, and the wear resistance is 60 to 80 times that of cemented carbide, which is suitable for cutting high hardness non-metallic materials.

Due to the high toughness provided by the cemented carbide matrix, the flexural strength of PDC inserts is up to 1500MPa, which can withstand high impact loads.

The coefficient of friction with non-ferrous metals is 0.1 to 0.3, which reduces the cutting force and cutting temperature and improves machining accuracy.

The thermal conductivity is 1.5 to 7 times higher than that of cemented carbide, which effectively reduces the temperature in the cutting area, and the heat-resistant temperature can reach 750°C (two minutes).

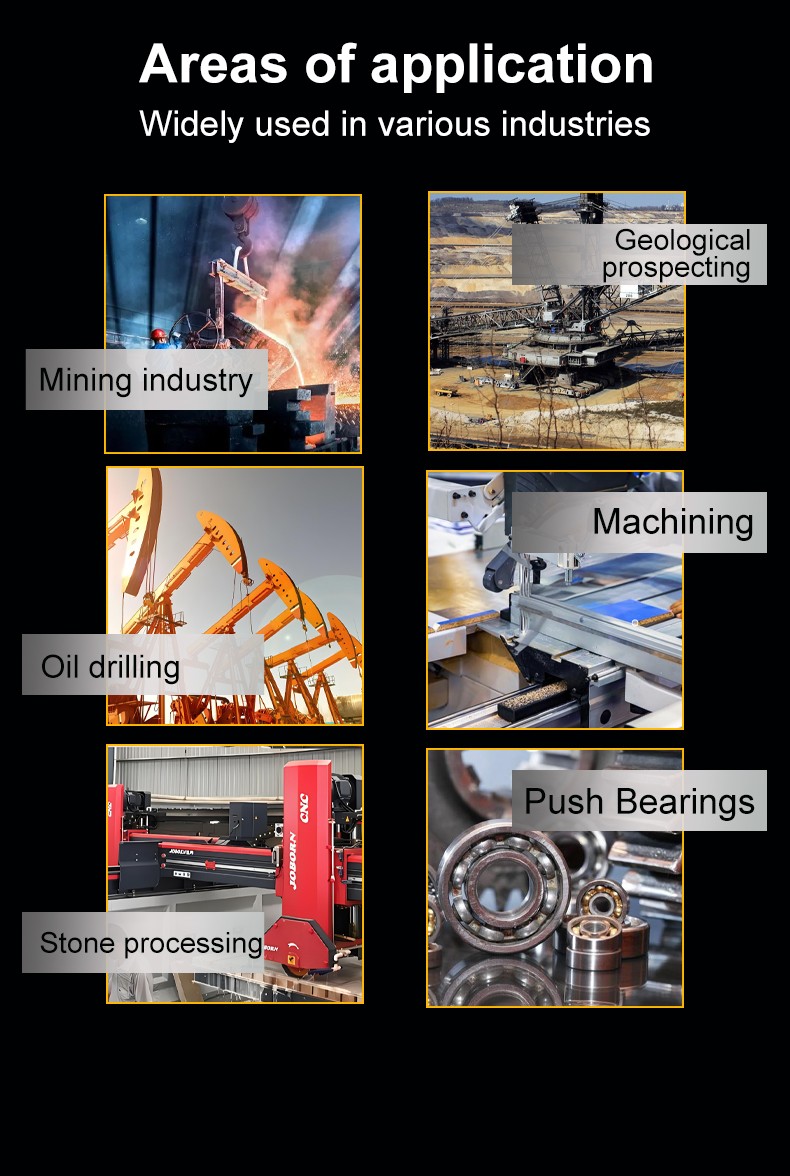

It is suitable for oil and gas drilling, geological exploration, coal mining, mining and stone processing, etc. It significantly improves drilling efficiency and reduces costs.