Under what circumstances choose cemented carbide stamping die

The batch of workpieces produced should be considered in the selection of blanking die materials.

If the batches are not large, it is not necessary to choose high-life die materials; the material of the

punched workpiece should also be considered, and the applicable die materials for different materials

are also different. For blanking dies, wear resistance is an important factor in determining the life of

the die, so under what circumstances do we need to use cemented carbide stamping dies?

The larger the number of carbides, the better the wear resistance. The wear resistance of commonly

used stamping die steels is carbon tool steel - alloy tool steel - matrix steel - high carbon high

chromium steel - high speed steel - steel bonded carbide - cemented carbide.

When the batch of workpieces is extremely large, it can be considered to choose cemented carbide

or steel-bonded cemented carbide with higher hardness and wear resistance than various mold steels.

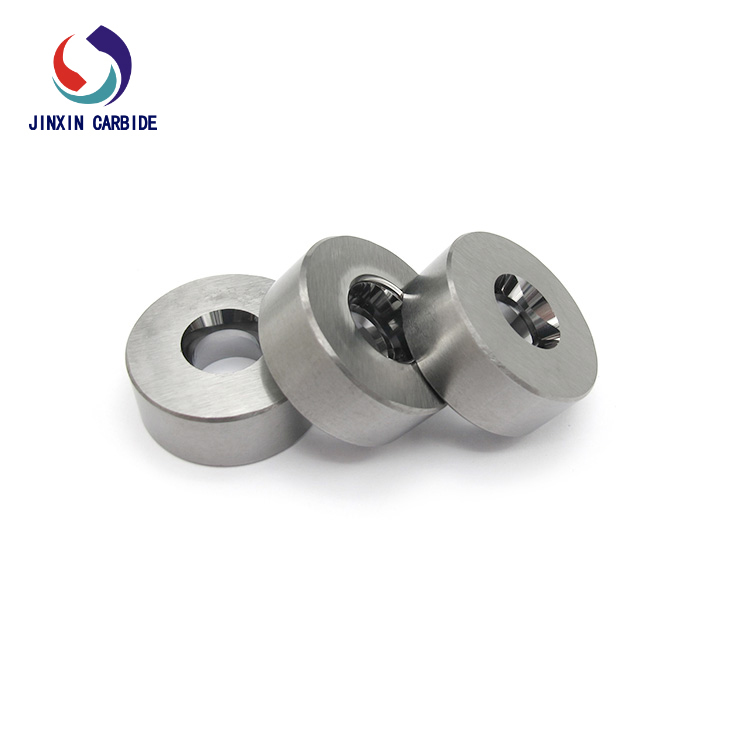

The cemented carbide used as the mold material is tungsten-cobalt.

With the increase of cobalt content, the toughness and bending strength increase and the hardness

decreases. For molds with low impact force, you can choose YG10X with low cobalt content; for molds

with medium or large impact force, you can choose YG15 or YG20 with high cobalt content.

The disadvantage of cemented carbide is that it has poor toughness and is difficult to process.

As a working part of a mold, it can be designed as an inlaid structure.

The performance of steel-bonded carbide is between that of cemented carbide and high-speed steel.

It can be machined and heat treated, and can be used to make complex high-life molds.

The steel-bonded cemented carbide used as a blanking die includes DT, GT35, TLMW50, GW50, etc.