Types of Tungsten carbide rollers

There are various types of tungsten carbide rollers, and each type has its unique characteristics and application areas. When categorized according to their structure, they can be divided into integral rolls and combined rolls.

Integral rolls: the whole roll is made of tungsten carbide material, or tungsten carbide material in the core shaft outside the overall coating. This structure of the roll has high strength, good integrity, and can well transfer the rolling force. In some of the roll strength and precision requirements of the occasion, such as high-precision cold rolled thin plate production line, the overall tungsten carbide roll can provide more stable rolling performance.

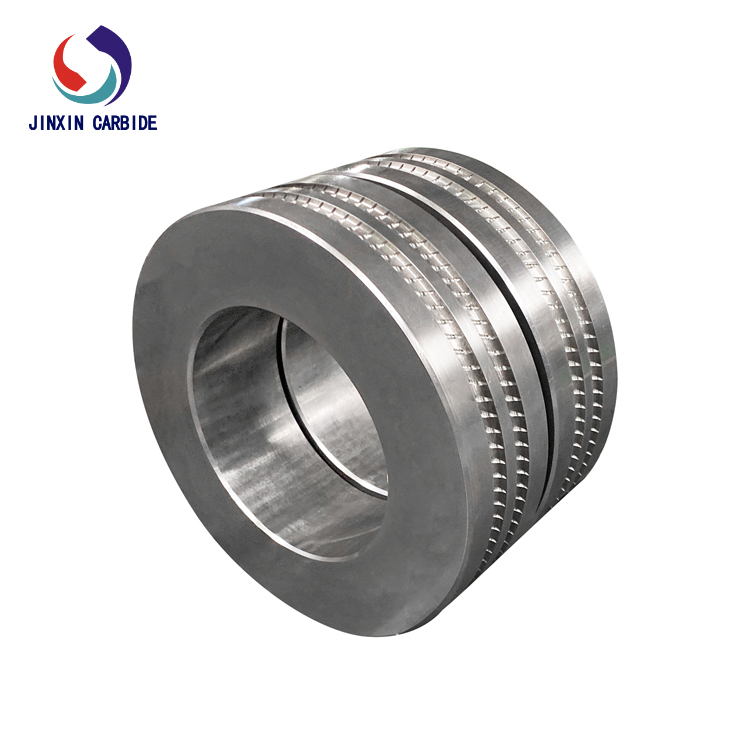

Combined rolls: usually made of tungsten carbide roller sleeve and other materials (e.g. steel) combined with a mandrel. The use of tungsten carbide roller cover is to take advantage of its high hardness and wear resistance, the use of other materials for the mandrel is mainly to consider the cost and structural strength. This structure of the roll is easy to manufacture and maintenance, when the roll sleeve wear, you can replace the roll sleeve and retain the mandrel, reducing maintenance costs. For example, in the application of some large rolls, the combined structure can ensure the performance of the roll while reducing material costs.