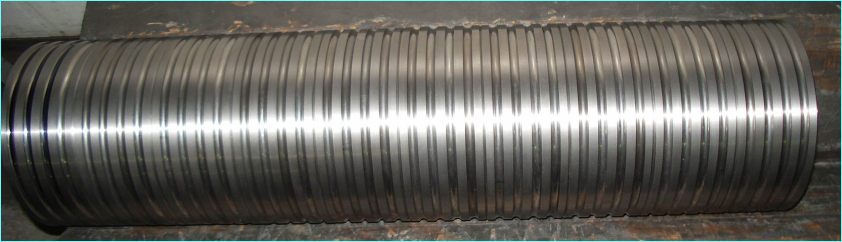

Tungsten carbide roll cooling

Tungsten carbide roll Cooling is to reduce the thermal stress fatigue impact of high temperature on the groove surface during rolling, so as to reduce the occurrence of hot cracks, delay the expansion of hot cracks, and reduce the promotion effect of temperature on corrosion. In order to reduce the degree of cracking, improve the service life of the roller ring, prevent the rapid expansion of hot crack caused by malignant roll breaking.

Tungsten carbide roll The water pressure of cooling water is too low and the water quantity is insufficient, which will lead to the high temperature of the roller ring and the great thermal stress, resulting in the expansion and destruction of the roller ring. Low water pressure and water pressure will lead to hot crack and hot corrosion of the rolling groove, which will reduce the rolling quantity of the rolling groove, and even lead to crack of the roll ring. If the water pressure is too large, the cooling water is easy to rebound, and the cooling effect can not be achieved.

Cooling water pressure requirements in 0.4 ~ 0.6mpa;

The amount of cooling water should be controlled at 250 ~ 300 l/min; The direction of cooling water spraying is radial, and the rotation direction of roller ring is 15 ~ 30O Angle, water can not scatter or fog, should be directly sprayed into the rolling groove.

The water temperature of cooling water should be controlled below 35℃.