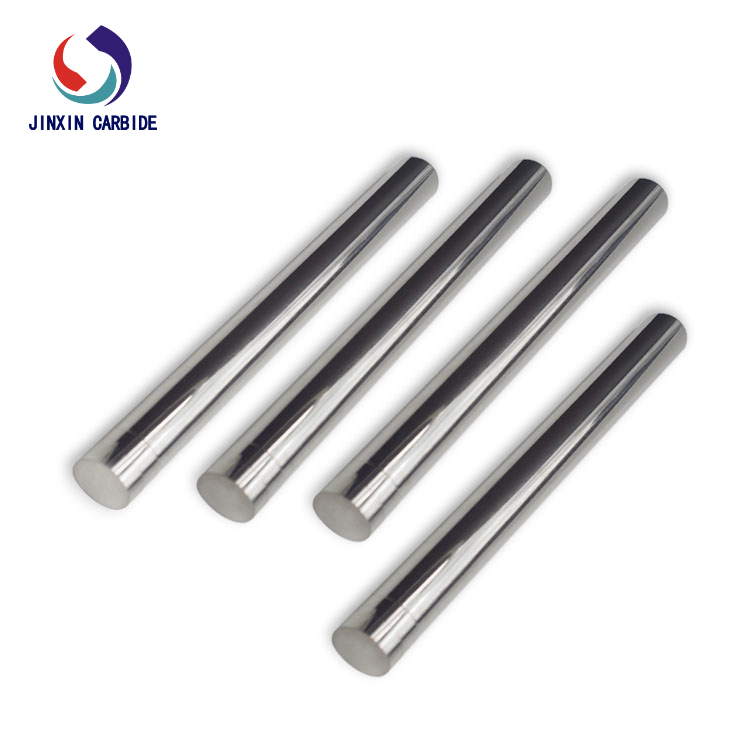

To undertake all kinds of carbide rod production and processing

Zhuzhou Jinxin has a complete cemented carbide rod production and processing technology production line, to meet the various needs of users, at the same time can flexibly change the production mode according to the needs of users. There are usually two ways to produce carbide bars. Today, zhuzhou Jinxin production of cemented carbide bar extrusion molding method.

Every coin has two sides, so the extrusion method of producing carbide bar has advantages and disadvantages. Although extrusion is a better way to produce long rods. It can be cut to any length desired by the user during extrusion. Of course, the length limit also needs to be within a reasonable range, which is the advantage of extruded round bar material.

The extrusion forming method of producing carbide bar also has disadvantages, such as long production cycle. Extrusion of small diameter round rod below 3mm, cutting off both ends will waste some material. The longer the length of carbide small diameter round rod, the worse the straightness of blank. Of course, the problems of straightness and roundness can be improved by external circular grinding in the later stage.

If the customer's production cycle is not urgent, the use of extrusion molding production of cemented carbide bar is a better choice. So Zhuzhou Jinxin can be flexible production according to the user situation.