The production process of tungsten carbide molds is revealed!

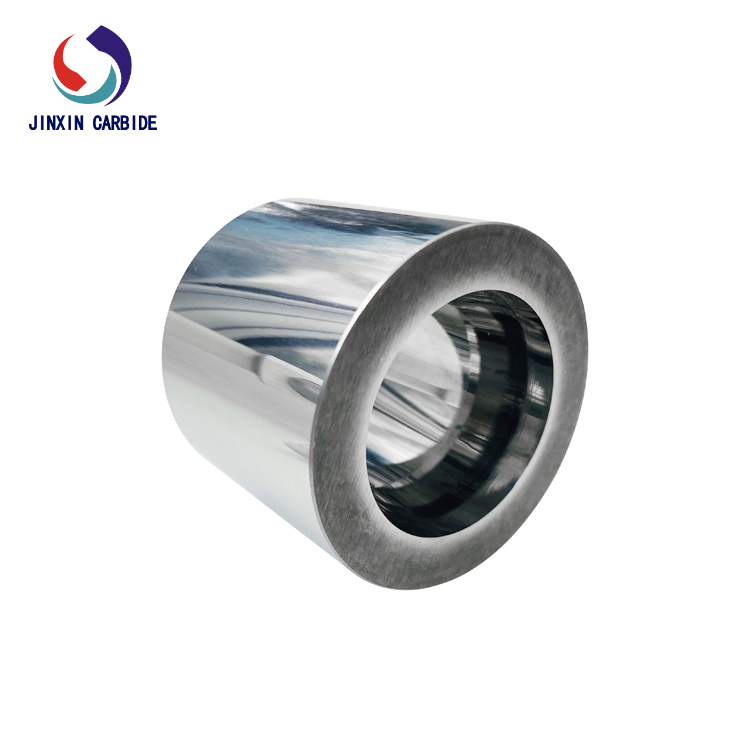

Tungsten carbide dies can be divided into four categories according to their uses. The first category is Tungsten carbide wire drawing dies, the second category is cold heading cold punching dies and shaping dies, and the third category is non-magnetic alloy dies used for the production of magnetic materials. The fourth type is hot working, which has a wide range of applications. So how is it produced? Let us find out together!

Every step in the production process of Tungsten carbide molds is critical and will directly affect the quality and performance of cemented carbide molds after production. Its key processes are as follows:

1: The raw materials are spray-dried: the mixture is prepared under the protection of high-purity nitrogen under a fully closed-loop mirror, which effectively reduces the possibility of oxygen increase of the mixture during the preparation process, and can effectively ensure the purity of the material and prevent the material from being dirty.

2: CIP (Cold Isostatic Pressing): 3000Mpa isostatic pressing machine is used to effectively prevent pressing defects and provide a good guarantee for pressing blanks with uniform density.

3: SP low pressure sintering strength: the maximum sintering pressure can reach 100 kg, so that the internal voids of the alloy body can be effectively eliminated, so as to obtain high hardness with good densification. The quality of the alloy mold may fluctuate.

4: Cryogenic treatment: effectively improve the microstructure of the cemented carbide mold, so that the internal stress of the cemented carbide mold can be effectively eliminated.

5: Analysis and testing: The national-level testing center can carry out comprehensive performance testing of various types, and the adoption of ultrasonic flaw detection methods ensures the stable quality of cemented carbide molds.

After the strict control of the above production process, the Tungsten carbide mold does not explode, has a long service life, and has a lower processing cost. However, there are few cemented carbide factories and companies with such production conditions in China. Since its establishment, Zhuzhou Jinxin has made some achievements in the field of cemented carbide. It has won the favor of global customers with stable product quality and rich product categories. It has independent import and export rights, and has established stable partnerships with many countries. Zhuzhou Jinxin has new process technology, efficient research and development of new products, strong supply capacity, and fast delivery guarantee, which is your best choice.