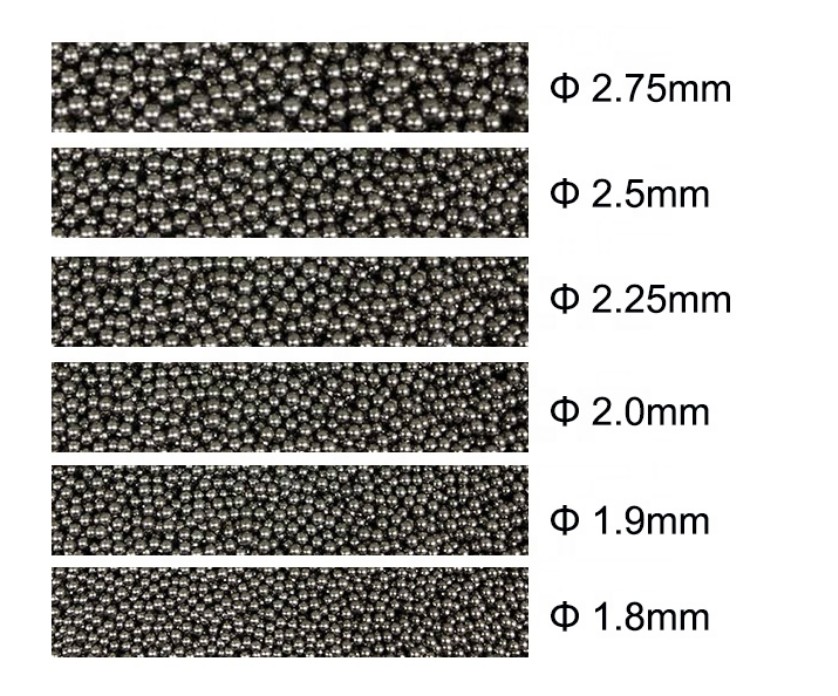

The preparation of tungsten alloy sphere by disc pelletizing method was revealed

Tungsten alloy sphere are widely used in many fields, and there are various preparation methods, among which the disk pelletizing method is the one with lower production cost.

Tungsten alloy disk pelletizing process requires the use of disk pelletizing machine. Disc clockwise rotation, to the region to join the mixed ore material, in the disc under the effects of the friction theory base, were disc with together do clockwise, due to the tilt installation disk, when the ore material was taken to a certain height, when its components is greater than the friction force of gravity, the particles will tumble down, mixed ore material circulation the movement for many times, The pelletizing process of tungsten alloy ball preparation is completed.

Tungsten alloy sphere disc pelletizing method has high production efficiency and low cost, but its disadvantage is that it needs classification, so it is not suitable for preparing one kind of ball billet, and the ball billet size is difficult to achieve higher dimensional accuracy. In the subsequent processing, the grinding amount is large and the product is jumpy, resulting in large processing stress, which needs to be eliminated by heat treatment.

We are a 12-year focus on high-performance cemented carbide non-standard production and processing base, will be assessed according to customer needs or drawings provided, try to meet customer needs, help customers solve problems.