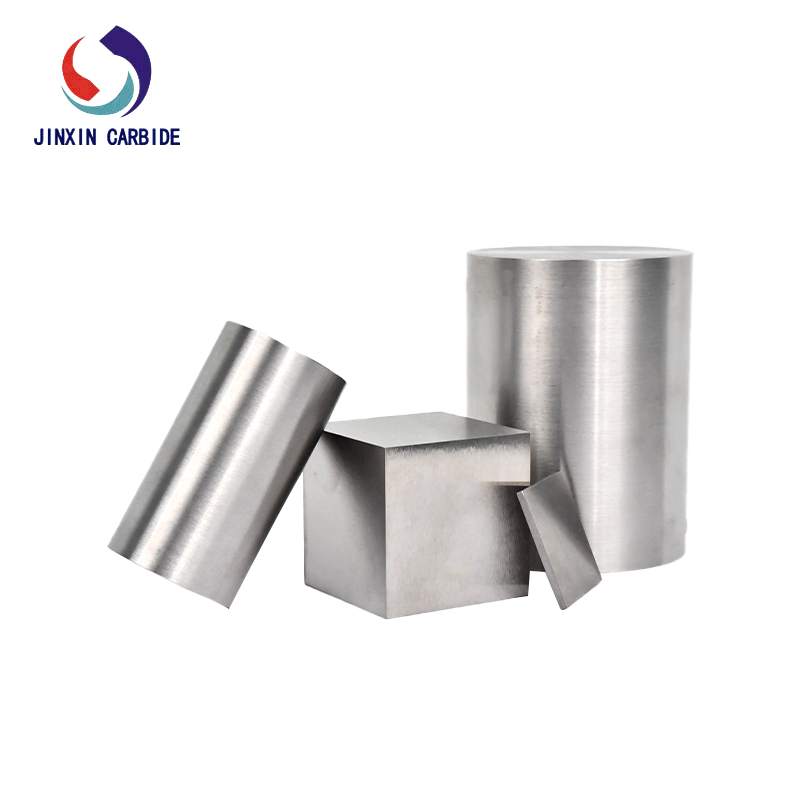

The differences between tungsten cube counterweight and tungsten cylinder counterweight?

The difference between tungsten cube counterweights and tungsten cylinder counterweights is not only obvious in shape and size, but also in their adaptability and application scenarios.

The tungsten cube counterweight is relatively better in stability, especially in the plane can be placed smoothly, not easy to roll, while the tungsten cylinder counterweight is more dominant in some application scenarios with rotational requirements, its shape is more in line with the mechanical characteristics of rotating bodies, can be better adapted to rotary movement. For example, in automobile tire balancing weights, tungsten cylinder counterweights can fit better in the circumferential position inside the tire.

Tungsten cube counterweight are more suitable for applications that require precise balancing and stabilization. For example, they are used in high-end machine tools to balance the weight of the spindle unit and reduce the burden on the screw and motor. It is also commonly used in military weapons, aerospace and other fields to meet the strict requirements for counterweight materials.

The shape of the cylinder makes it easier to rotate and roll for applications requiring dynamic balancing. For example, tungsten cylinder counterweights are used to fine-tune the balancing properties of equipment in areas such as flywheels, ballasts, and racing cars. They are also commonly used for weighting sports equipment (e.g. golf heads, badminton rackets) to enhance the performance and experience of the equipment.