How to maintain the wire drawing die to be wear-resistant?

How to maintain the wire drawing die to be wear-resistant?

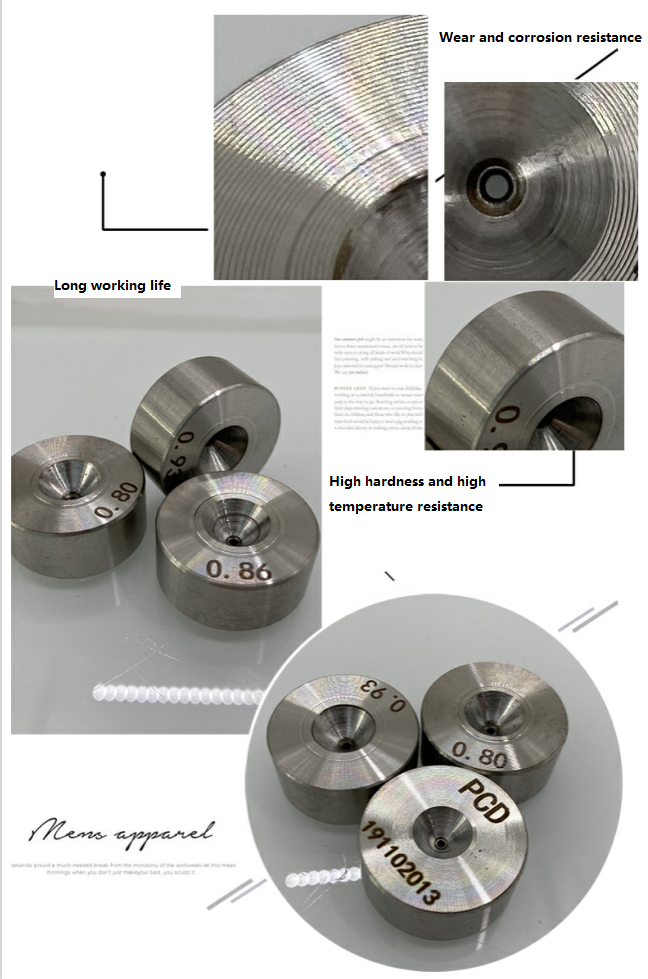

For carbide wire drawing die, we are most concerned about how to operate the specification, how to maintain the problem of wear resistance, today let me share how to maintain the wire drawing die be wear resistant.

Tungsten carbide wire drawing die in the use of a period of time, its internal parts will gradually wear so as to be damaged, resulting in tungsten carbide wire drawing die work performance and accuracy reduced, due to the operator's carelessness and maintenance of improper use, but also make tungsten steel wire drawing die is broken or product quality decline, or even cause production downtime, how to remove and avoid these failures, which requires tungsten carbide mold technicians to master the relevant Mold repair technology, so that any time a failure occurs, it can be handled and repaired at any time, so that it can be restored to normal use as much as possible, has played the maximum potential of the mold.

In order to improve the service life of cemented carbide wire drawing dies, the following points should be noted in the selection and use process.

1、Rational selection of die grade

According to the physical and mechanical properties of the material and the size of the material, choose the die grade reasonably. For example, choose YG6 or YG8 for steel bars, non-ferrous metal wire or bars with a diameter of 20mm or less; YG8 for 20-50mm; YG11 or YG15 for 50mm or more.

2、Check the wire drawing machine in time

3、Appropriate cleaning of the wire

Before wire drawing, the surface of the wire should be properly cleaned, otherwise it is easy to reduce the service life of the die and also easy to produce scratches on the wire, affecting the surface quality.

4、Choose the right lubricant

To use high quality lubricants, such as: wire drawing powder, etc., in order to improve the service life of the wire drawing die.

5、Lubrication protection

Do a good job of cooling the carbide die and lubricate the working area, especially the high-speed wire drawing die, so as to improve the service life of the wire drawing die.

6、Rational choice of compression rate

To choose a reasonable compression rate according to the size and performance of the drawn wire, the compression rate is too small, resulting in high production costs; the compression rate is too large, resulting in lower die life, and even blowing up the die.

7, pay attention to control the surface condition of the metal material

In the drawing process, if you find that the inner hole of the mold is adhered to the metal particles, and the metal surface is scratched should immediately stop, the adhered metal particles will be removed, the inner hole of the mold polished. Every time you use it, the metal particles adhering to the inner hole should be handled carefully and cleanly.

8、Check the mold regularly

Check the mould regularly to find out the metal particles stuck in the inner hole in time.

9、Store the mold properly

Keep the wire drawing dies properly, and protect them with anti-rust oil if they are not used temporarily.

Any interested items please feel free to contact:

Contact: Julia

Mob:+8618073319589

Wechat:18073319589

Whatsapp/Skype: +8618073319589

E-mail:sales06@jxcarbide.com