How to judge the quality of carbide valve core and valve seat

As a key component, carbide valve core and valve seat are essential for the sealing performance and durability of the valve.However, there are various carbide valve core and valve seat with different quality levels on the market, and how to judge their quality has become an important issue. Here are some methods to judge the quality of carbide valve core and valve seat.

First, the brand and manufacturer information of the valve core and valve seat should be checked.Qualified carbide valve core and valve seat should have clear brand and manufacturer information, which proves that its production process is subject to strict quality control.By querying relevant standards and certification information, you can further understand the quality and reliability of the product.

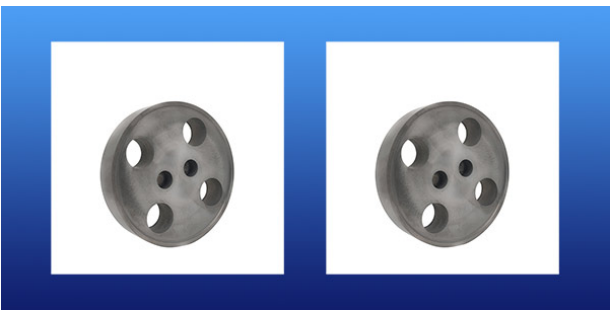

Secondly, the appearance of the carbide valve core and valve seat needs to be checked. The surface of the valve core and valve seat should be smooth and free of defects such as cracks and pitting, and the color should be uniform. If there are obvious flaws or uneven color, it is likely that the quality is unqualified or inferior raw materials are used.

Next, physical performance tests can be performed. Common test items include hardness, wear resistance and corrosion resistance. The hardness test can be performed by Rockwell hardness tester or Vickers hardness tester. Qualified carbide valve core and valve seat should have a certain hardness to ensure its wear resistance and corrosion resistance.

In addition, the sealing performance test can also be performed. By assembling the carbide valve core and valve seat into the corresponding valve, a sealing test is performed to observe whether it can be completely sealed and leak-free. Qualified valve core and valve seat should have good sealingperformance and be able to maintain a reliable sealing effect under various working conditions.