How to choose the good tungsten carbide plate?

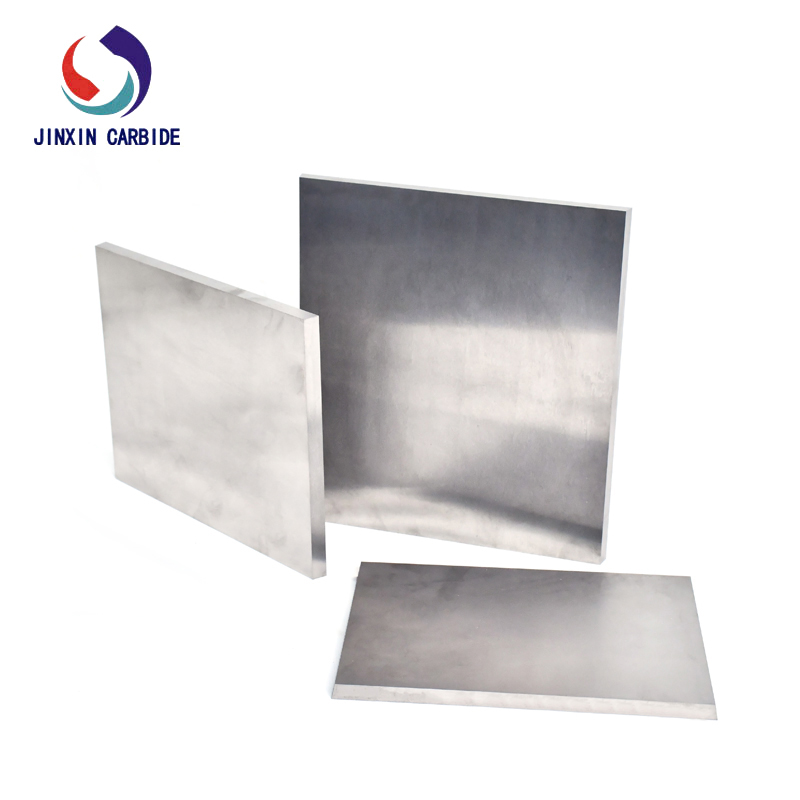

Tungsten carbide plates are widely used in mining machinery, mold manufacturing, chemical equipment and other fields due to their high hardness, wear resistance and corrosion resistance. Choosing tungsten carbide plates that meet the working conditions requires comprehensive consideration of material properties, processing technology and application scenarios.

For example, the content of tungsten carbide (WC) is usually between 80% and 95%. High content (≥90%) is suitable for high wear environments (such as mining drill bits), and medium content (85%-90%) takes into account both hardness and toughness (such as cutting tools). Fine grain (<1μm) products have high hardness but high brittleness, and coarse grain (>2μm) has better toughness. Generally, mining machinery is suitable for WC≥92%, fine grain, high hardness grade YG8C plates, and vacuum sintering or hot isostatic pressing (HIP) process products are preferred. Their density and performance stability are significantly better than normal pressure sintering.

In the face of complex use environments, it is recommended to consult suppliers in combination with specific working conditions to obtain customized solutions. Jinxin can provide you with ISO 9001 certification, third-party test reports (such as SGS), and preferably pass the wear test. Provide you with customized services.