How much do you know about the polishing process of tungsten carbide molds?

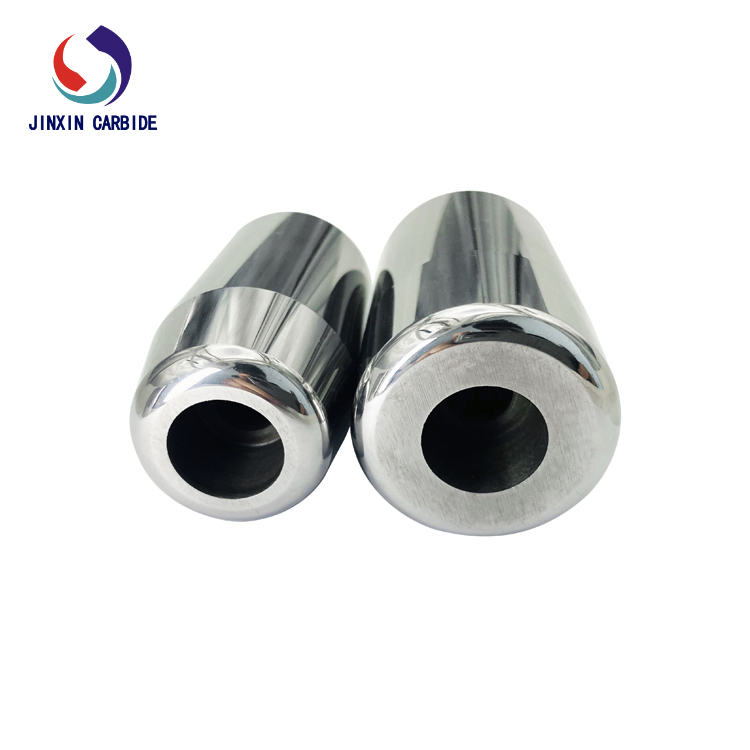

Tungsten carbide molds have excellent properties such as high hardness, high wear resistance, heat resistance and corrosion resistance, so they have a wide range of applications. In use, good polishing can improve the refractive index of light on the surface of the workpiece, which is brighter from a human visual point of view. , but the dimensions of the part have not changed and the unevenness of the surface has not changed.

Polishing is an important process in the processing of tungsten carbide molds. Among them, tungsten steel cemented carbide molds have a higher difficulty coefficient, but the polished molds are not only practical and beautiful, but also increase wear resistance. So what are the polishing processes?

1. Magnetic grinding and polishing

Magnetic grinding and polishing is the use of magnetic abrasives to form abrasive brushes under the action of a magnetic field to grind molds.

2. Chemical polishing

Chemical polishing is to make the microscopically protruding part of the cemented carbide mold dissolve preferentially over the concave part in the chemical medium, so as to obtain a smooth surface. This method can polish hard alloy molds with complex shapes, and can polish many workpieces at the same time, with high efficiency.

3. Electrolytic polishing

The principle of electrolytic polishing is the same as that of chemical polishing, that is, by selectively dissolving the tiny protrusions on the surface of the material to make the surface smooth. Compared with chemical polishing, the influence of cathode reaction can be eliminated,and the effect is better.

4. ultrasonic polishing

Put it in the abrasive suspension and put it together in the ultrasonic field, relying on the oscillation of the ultrasonic, the abrasive is ground and polished on the surface of the mold.

5. Fluid polishing

Fluid polishing relies on the high-speed flowing liquid and the abrasive particles carried by it to scour the surface of the cemented carbide mold to achieve the purpose of polishing.