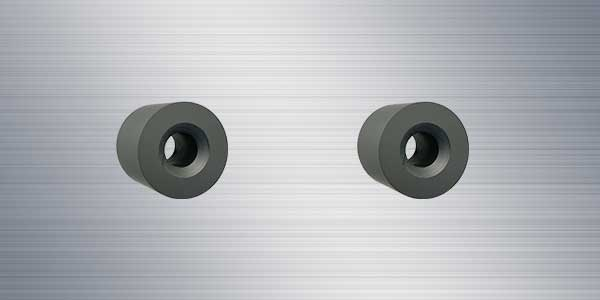

How about the wear parts carbide bushing?

How about the wear parts carbide bushing?

Cemented carbide bushing is one of Zhuzhou Jinxin's main products, and it is the most repurchased product by old customers. Why is Zhuzhou Jinxin's hard alloy bushing more popular than other manufacturers? What kind of advantages does it have that make it so popular.

1. Compared with other materials, the strength and hardness are higher, which can meet the requirements of the use conditions of independent anti-friction and wear-resistant parts such as bearing bushes.

2. The hard alloy bushing has a good affinity for lubricating oil, good self-lubrication, and more prominent anti-friction and wear-resisting properties.

3. Low friction coefficient, less wear and tear, thus longer service life. Under the same conditions of use, the frequency of replacement is reduced, thereby reducing the purchase cost of accessories.

4. High thermal conuctivity, fast heat dissipation, slow and low temperature rise on the grinding surface, and better protection against pairing friction.

5. Higher damping characteristics, vibration reduction and noise resistance.

6. Large bearing capacity, high density and corrosion resistance.

Carbide bushings are mainly used in the support of rotating shafts, various types of pump bearing bushes, motor bushings, and sealing bushings. Zhuzhou Jinxin can also produce and process cemented carbide bushings into various sizes and specifications according to the drawings or requirements of customers, and adapt to the machine to meet the needs of use.