Do you know the usage requirements of carbide roller ring

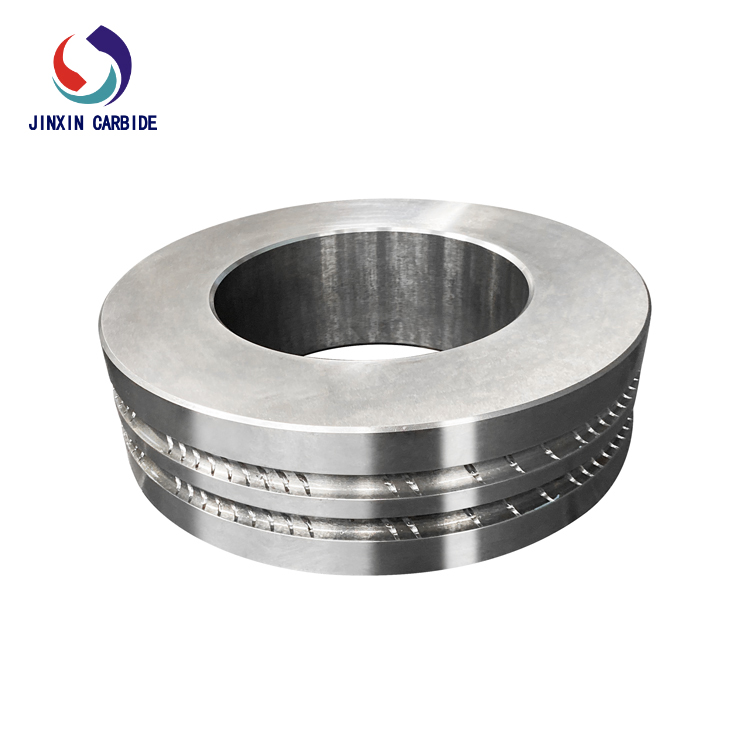

Tungsten carbide roll is a tool material with high hardness and high wear resistance, which is composed of tungsten carbide and bonding metal. In order to make the cemented carbide roller ring give full play to its advantages of high wear resistance, long life and high efficiency in high-speed wire rolling, the following matters should be paid attention to when purchasing and using cemented carbide roller ring:

1. Brand selection, according to the needs and rack to choose the best matching brand

2. Install the roller ring properly

3. Cooling and cooling water quality, cooling is to reduce the effect of thermal corrosion, thermal fatigue and thermal stress on ring during ring rolling, prevent ring breakage and delay the diffusion of cracks.

4. Reasonable amount of rolling, not excessive rolling.

5. Repair of rolling groove, rolling groove rolling to a certain time will appear microcracks, need to be thoroughly ground to remove microcracks.

Zhuzhou Jinxin is specialized in the production of cemented carbide roller ring manufacturers, products before the factory finished product testing, unqualified products will not flow out.