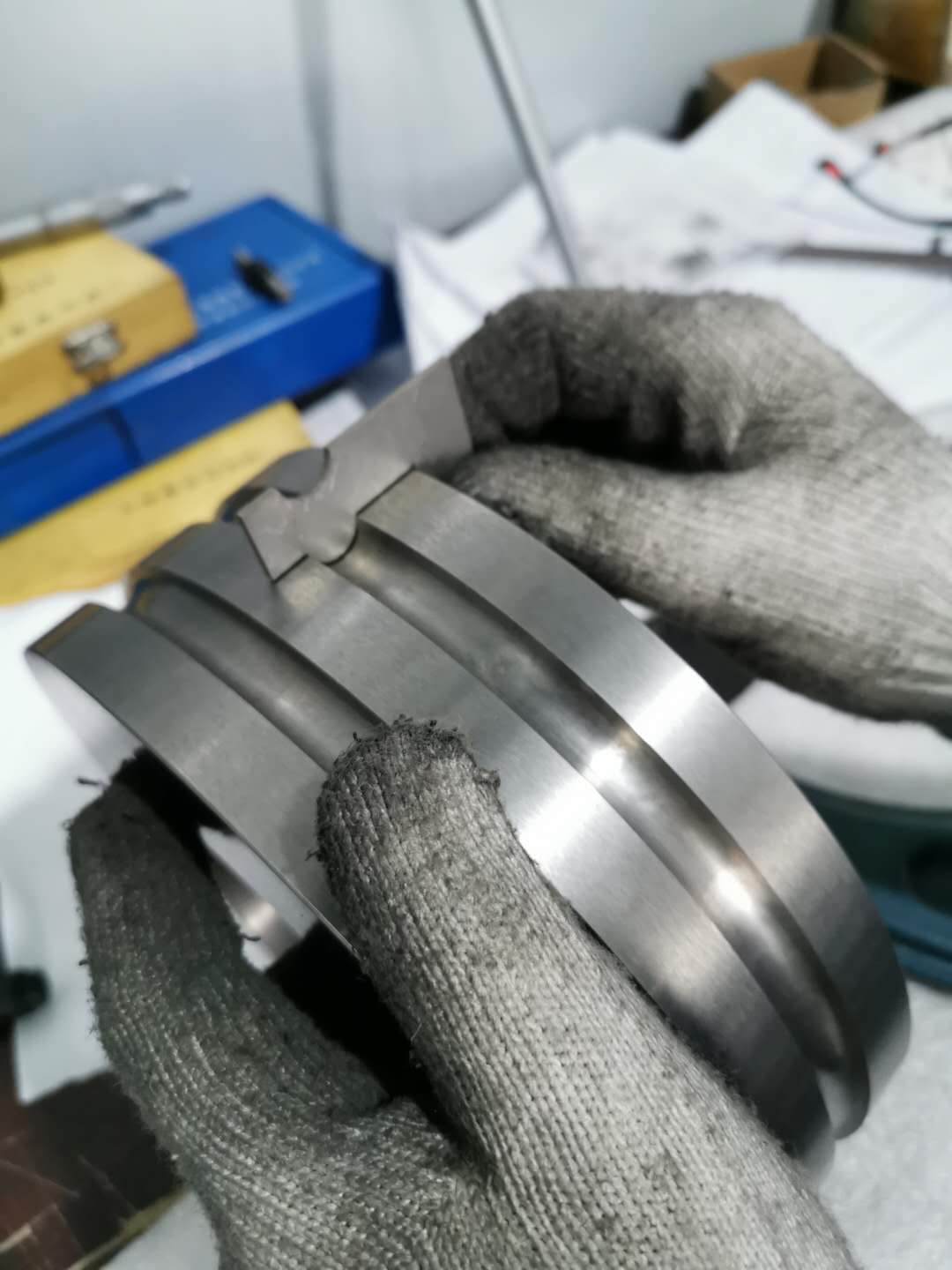

Corrosion effect of tungsten carbide roller in use

The corrosion results in the loss of the bonding phase of the surface layer of cemented carbide, which makes part of the carbide exposed on the surface, and the bond between adjacent carbides becomes fragile, and the damage rate is correspondingly increased.

Tungsten carbide roll. Pure WC-CO has corrosion resistance in cooling water with PH value greater than 7.2. When the cooling water PH value is low to 5, WC-(Co-Ni-Cr) brand can still be used normally. The PH value of cooling water is one of the most important parameters to determine the corrosion degree of the roller ring, of course, other factors will also affect, such as the temperature of the medium, conductivity, flow rate and so on.

The methods of corrosion treatment include changing the grade of Tungsten carbide roll. and adding alkaline solvent in cooling water.