Classification of tungsten carbide rings

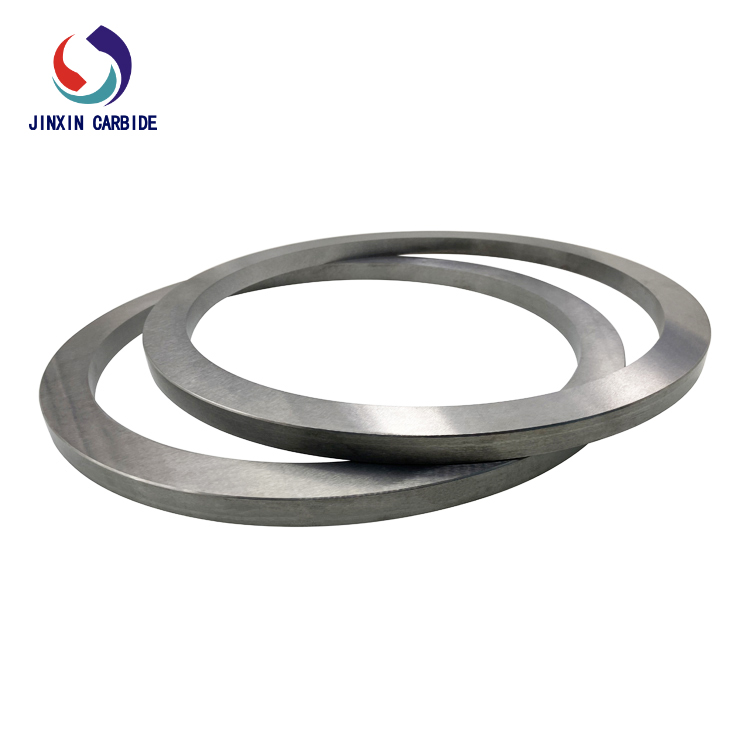

tungsten carbide ring due to wear resistance, durability and corrosion resistance, long service life, so the application of a wide range of applications, application fields are not the same, natural name is also different, together to understand the classification of these cemented carbide rings.

Cemented carbide ring is used in valves, screws, pumps, compressors and other sealing parts, mainly to prevent liquid, gas and other leakage sealing function, often called oil seal ring.

Cemented carbide ring installed on the machine or device to form a plane, rotating surface sealing combination, is a mechanical assembly, so also known as cemented carbide mechanical seal, to prevent high pressure leakage, resist the pressure and stress caused by component movement or vibration. These seals have a complex structure and are divided into fixed and movable parts. These seals act as anti-vibration devices, bearings, actual seals, and sometimes as joints. They are used in a wide range of applications, including pumps, compressors, mixers, agitators, and steam turbines. Although all are made of hard alloy, but the shape of the size is also different.

Application in all fields of carbide rings, USES different, the shape is different also, size, accuracy requirement is not consistent, so the custom demand for hard alloy ring is also very much, zhuzhou jinxin undertake various non-standard custom of carbide rings, according to your purpose, recommended brand of working conditions, and according to the drawing of non-standard custom tungsten carbide rings.