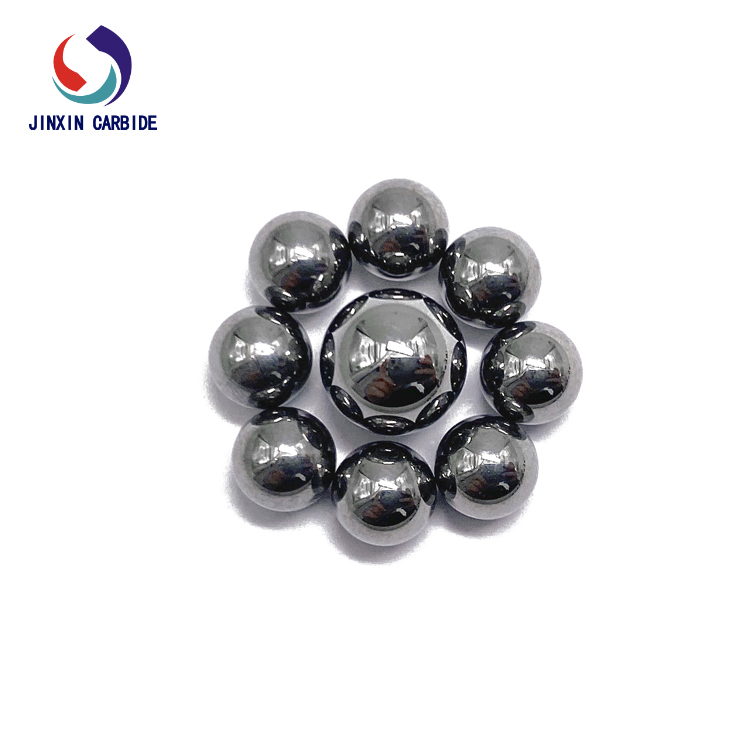

Classification of tungsten balls

Tungsten ball is a product made of tungsten carbide alloy, also known as tungsten steel ball, can be used in bad environment, so the utilization rate is very high, it has a wide range of applications, its hardness is greater than 90.5, density is 14.9g/cm3, often instead of steel ball products.Today we mainly understand the classification of tungsten steel ball in detail.

Type 1: blank ball

Without fine grinding processing on surface, the product surface has a belt, usually used for grinding, including grinding a variety of powder products.

Type 2: fine grinding ball

With further fine grinding and made on the basis of the blank ball, the surface of the cemented carbide fine grinding ball can reach the G25 finish, with high hardness and wear resistance.

Type three: punching ball

Made of tungsten carbide material with high hardness and impact resistance, the surface of the punching ball is usually fine ground.

Type four: bearing ball

The main component is tungsten cobalt alloy, which has high hardness and good wear resistance (its wear resistance is tens of times to hundreds of times of the steel ball), and is mainly used in precision bearings.

Type 5: valve ball

It is a high temperature sintered alloy material composed of refractory metal WC and cemented metal Co or Ni. The product has good stability and can adapt to the harsh working environment of drilling industry.