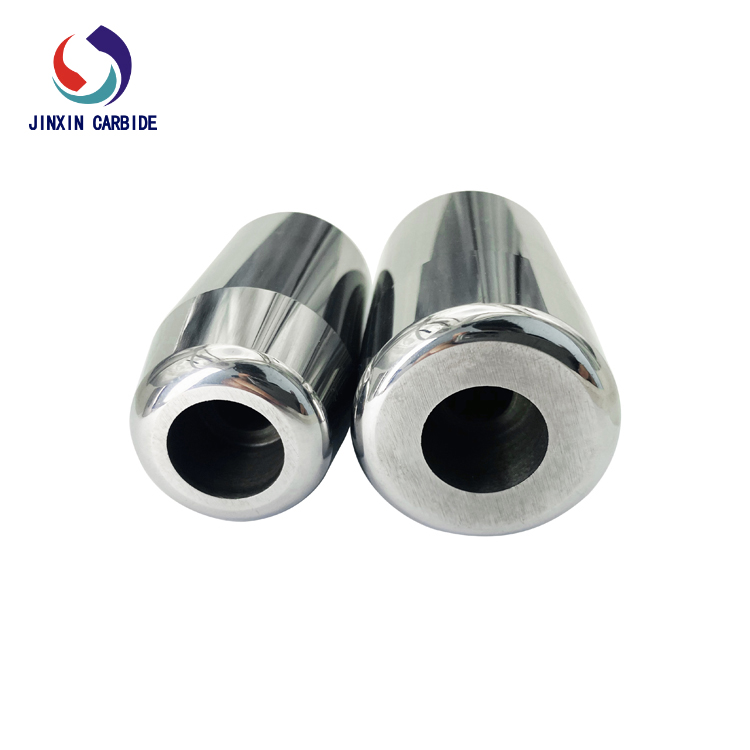

Carbide spool in steam trap

Tungsten carbide spool is an important part of the steam trap. Because of the working conditions of the trap, the spool requires high temperature and durability, and the tungsten carbide spool is currently on the market that meets this condition and can adapt to this type of trap. working condition products.

Let's take a look at the working environment of the carbide spool. Let's take the disc-type steam heat preservation type steam trap as an example. Its principle depends on the flow rate and volume change when steam and condensed water pass through. Different thermodynamic principles cause different pressure differences between the upper and lower sides of the valve plate to drive the valve plate to open and close the valve. , add a layer of shell outside the steam chamber.

The inner chamber of the shell is connected with the steam pipe, and the main steam chamber of the steam trap is kept warm by using the steam of the pipe itself. The temperature of the main steam chamber is not easy to cool down, the steam pressure is maintained, and the steam trap is tightly closed. When condensed water is generated in the pipeline, the temperature of the trap shell will drop, and the trap will start to drain; if there is no condensed water in the superheated steam pipeline, the trap will not open, and the working quality is high. The valve body is alloy steel, and the valve core is hard alloy valve core. The maximum allowable temperature of the valve is 550°C. It is durable and has a long service life. It is a special steam trap for high-pressure and high-temperature superheated steam.

The use of disc steam heat preservation type steam traps must have a hard alloy valve core, high-quality hard alloy valve core, high temperature resistance, and non-toxic and harmless under high temperature conditions, because some materials are heated under high temperature conditions. , will emit odor, gas, and melt. Therefore, the choice of material is very important. In this case, it is necessary to choose a high melting point, the preferred carbide valve core.