Analysis of the advantages of cemented carbide rod

Cemented carbide is an inorganic compound containing equal amounts of tungsten and carbon atoms. In its most basic form, it is a subtle gray powder, but it can be used in industrial machinery, tools, abrasives, and forms for use. Cemented carbide contains three times as much carbon as steel and has a denser crystal structure than steel or titanium. Its hardness is comparable to diamond, and it can only be ground into hard alloy, polished with cubic boron nitride abrasive.

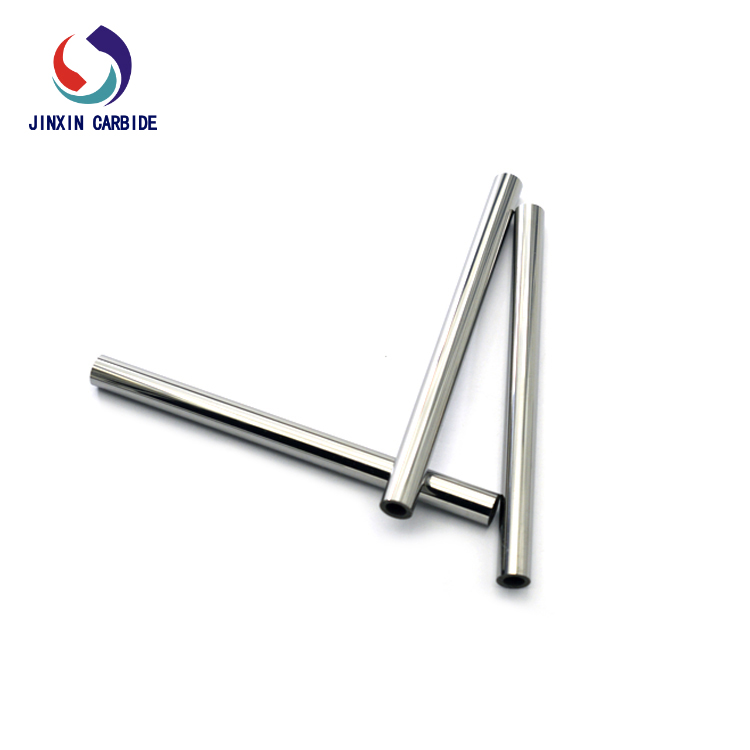

Cemented carbide rod is a new technology and new material. Mainly used in metal cutting tool manufacturing, wood, plastic hardness and wear resistance of the manufacturing of corrosive products and other industries. The main characteristics of cemented carbide bars are stable mechanical properties, easy to weld, high wear resistance and high impact resistance.

Grades YG6, YG8, YG6X are more wear-resistant than MK6, it can be used for hard wood, processing aluminum alloy profiles, brass bars and cast iron, etc., YG10 is wear-resistant, knock resistant, used for processing hard wood, softwood, ferrous and non-ferrous metals.

Carbide rods are used as cutting and drilling tools, as well as as input needles, parts and structural materials for various roll wear. In addition, it can be widely used in many fields, such as machinery, chemical, petroleum, metallurgy, electronics and defense industries.