Tungsten welding rod

Brand Name : JINXIN

Place of Origin : CHINA

Delivery Time : 20 -25 DAYS

Supply Ability : 1000TON/MONTH

1.With strict tolerance extent control 2.Enjoy excellent wear resistance & high toughness 3.Have very good thermal & chemical stability 4.Anti-deformation & deflection 5.A special Hot Isostatic Press (HIP) process provides quality improvement to the finished products to ensure material reliability. Welcome your inquiries. Also we can send you some samples for your testing.

Tungsten welding rod

A tungsten welding rod, often referred to as a tungsten electrode, is a crucial component in tungsten inert gas (TIG) welding.Tungsten electrodes are typically made from pure tungsten or a tungsten alloy. Pure tungsten electrodes are designated as "WP" (e.g., WPure) while alloys are designated with various codes like "WT20" (2% thoriated tungsten), "WC20" (2% ceriated tungsten), and others.

In TIG welding, the tungsten welding rod serves several purposes:It carries the electric current necessary to generate the arc between the electrode and the workpiece.It remains relatively stable at high temperatures, allowing for precise control over the welding arc.It does not melt during welding, but rather facilitates the transfer of electrical energy to the workpiece.

Carbide rod characteristics

1. Made by high quality tungsten carbide superfine powder

2. Precision equipment with 10MPa HIP-Sinter stove standardized manufacture.

3. High hardness and high strength

4. Special advantages: Red hardness, wear resistant, high elasticity modulus, TRS, chemical stability, impact resistant, low dilatation coefficient, heat conduction and electric conduction same with iron.

5. Special technology: high pressure sintering of high temperature vacuum. Reduce porosity, reduce compactness and mechanical property. Various grade, types and sizes.

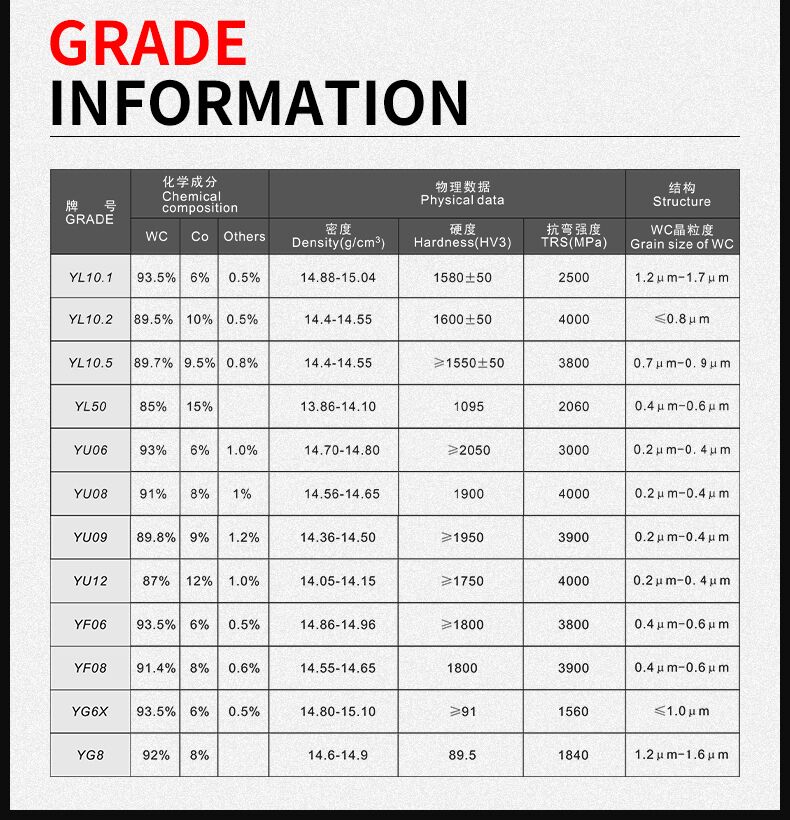

6. Different grade for your reference.

Contact:vincent

Mob: +8613357331966

wechat:13357331966

WhatsApp: +8613357331966

Email: jinxin012@ojinxin.com