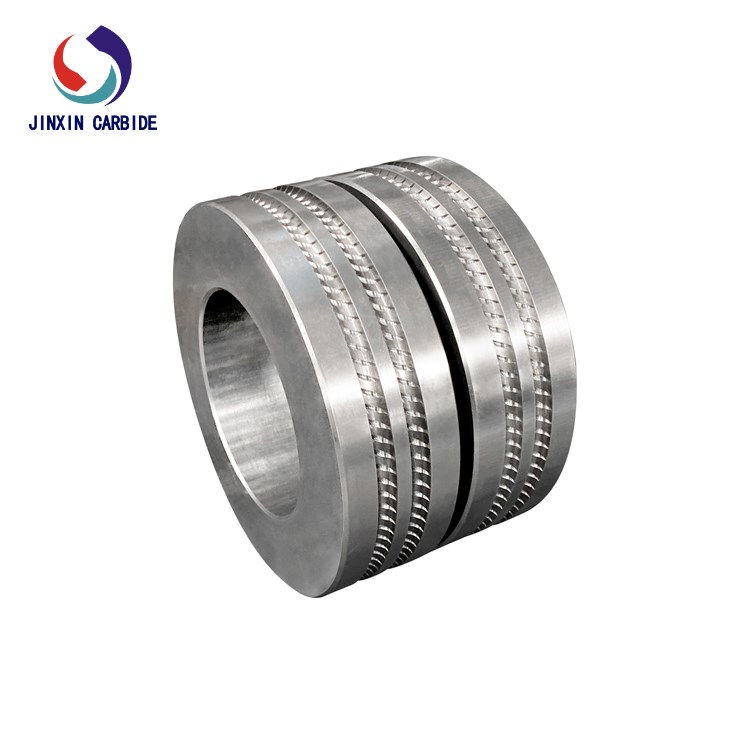

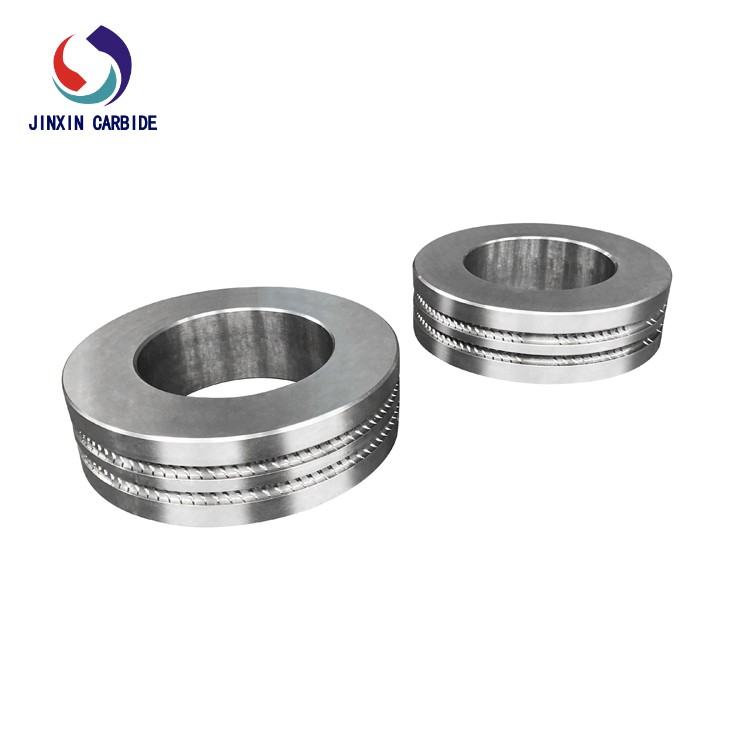

Hot Rolled Tungsten Carbide Roll Ring

Brand Name : jinxin

Place of Origin : china

MOQ : 4pcs

Packaging Details : Case

Delivery Time : 7-15days

Supply Ability : 10 ton/month

Matierial : Tungsten Carbide

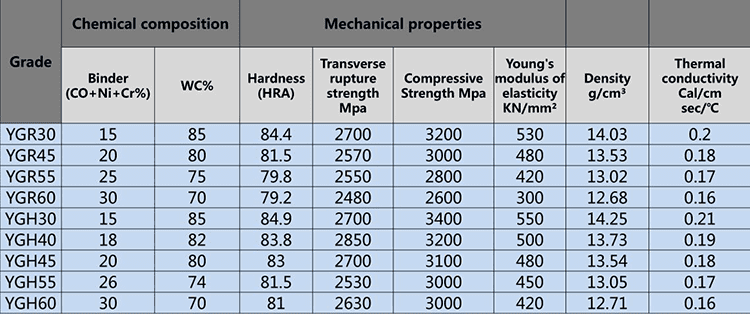

Product name: Tungsten carbide ring roller Common material: YGR30, YGR45, YGR55, YGR60, YGH30, YGH40 etc. Below are grade of binder between 15% -30%, for the tender requests Application: YGR30: Good toughness, wear resistance, corrosion resistance and thermal crack resistance. Used in most stands of the finishing mills and in the rear stands of common mils. YGR40: Good toughness and thermal crack resistance, good for general purposes.

Tungsten carbide rolls are widely used in metal forming, especially in hot rolling industry mainly for intermediate and last finishing stands to ensuring superior surface finish and dimensional stability of processed metal products. Rolls are also commonly used for wire flattening, descaling and straightening applications.

Common material of tungsten carbide rolls: YGR30, YGR45, YGR55, YGR60, YGH30, YGH40 etc.

Tungsten carbide rolls application:

YGR30: Good toughness, wear resistance, corrosion resistance and thermal crack resistance. Used in most stands of the finishing mills and in the rear stands of common mils.

YGR40: Good toughness and thermal crack resistance, good for general purposes. Used in most stands of the finishing mills and in the rear stands of common mils.

YGR55: Good impact resistance. Used in the stands of pre-finishing rolling mills for hot rolling rebars and they can be machined with turning and milling.

YGR60: Good impact resistance. Used for hot rolling rebars and in the first and second stands of pre-finishing rolling mills and they can be machined with turning and milling.

Tungsten carbide roller rings dimension:

See the below information or as per customer requirement.