Concrete Pump Spare Parts Kyokuto/Sani/Zoomlion/Putzmeister Small S Valve connected with Wear Plate and Wear Ring

Brand Name : JINXIN

Place of Origin : CHINA

MOQ : 10sets

Packaging Details : Case

Delivery Time : 20-30 days

Supply Ability : 1000000kg/month

Matierial : Tungsten carbide

Type : All

High density Good machinability High modulus of elasticity Strong corrosion resistance Non-poisonous ,no pollution Good mechanical properties

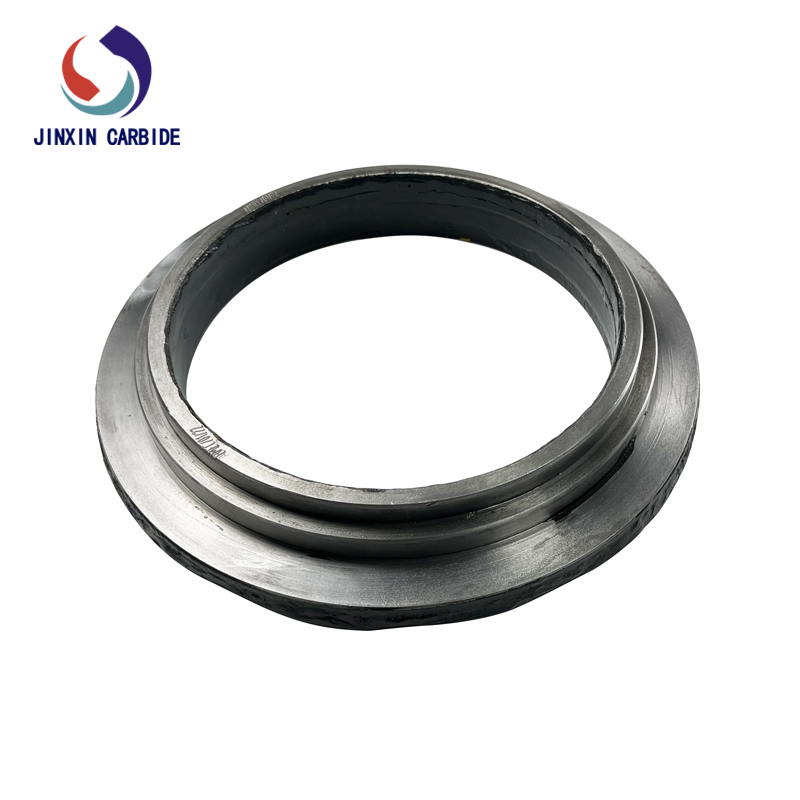

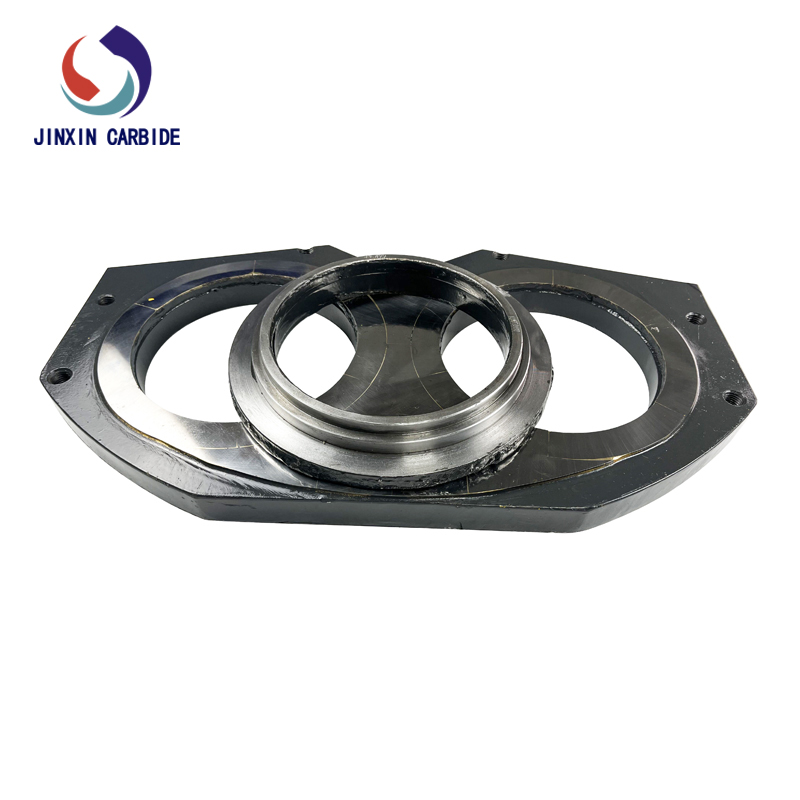

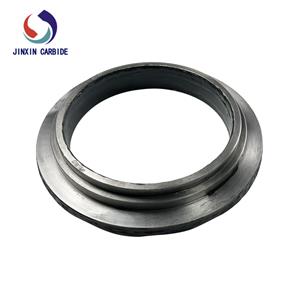

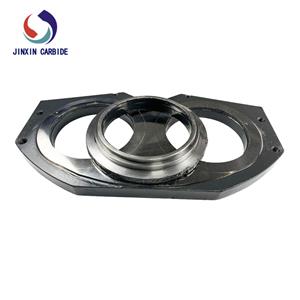

Factory Wholesale Tungsten Carbide Concrete Pump Spectacle Wear Plate & Wear Ring

Features:

HRC: ≥ 63°

Carbide HRA: ≥ 86°

Bending strength: >2500N/mm²

Material:Tungsten carbide,Q2358 steel; VAUTID-150 electrode imported from Germany.

Service Life: According to using different types of wear plate, Service life has some differenl, about 30000--60000CBM

Types: DN200,DN230 , Wear-resistant castings ; Holistic tungsten carbide; “L”Shape tungsten carbide; Doubletungsten carbide ring ; Double tungsten carbide ; Tungsten carbide.

| Model | Wear Plate | Cutting Ring | ||||

| Suitable pump type | Diameter | Length | Width | Outside Diameter | Inside Diameter | |

| (mm) | (mm) | (mm) | ( mm ) | ( mm ) | ||

| PM | Trailer-mounted concrete pump | 190 | 570 | 320 | 260 | 190 |

| Trailer-mounted concrete pump | 220 | 570 | 340 | 282 | 220 | |

| Truck-mounted concrete pump | 220 | 560 | 308 | 283 | 217 | |

| Zoomlion | Trailer-mounted concrete pump | 195 | 590 | 330 | 261 | 190 |

| Truck-mounted concrete pump | 220 | 630 | 372 | 283 | 220 | |

| Truck-mounted concrete pump | 225 | 630 | 372 | 293 | 225 | |

| Truck-mounted concrete pump | 235 | 690 | 390 | 310 | 235 | |

| Sany | Trailer-mounted concrete pump | 192 | 580 | 355 | 264 | 192 |

| Truck-mounted concrete pump | 225 | 630 | 383 | 295 | 225 | |

| Truck-mounted concrete pump | 235 | 640 | 430 | 315 | 235 | |

| Schwing | Trailer-mounted concrete pump | 178 | 534 | 302 | 262 | 195 |

| Trailer-mounted concrete pump | 195 | 534 | 302 | 262 | 195 | |

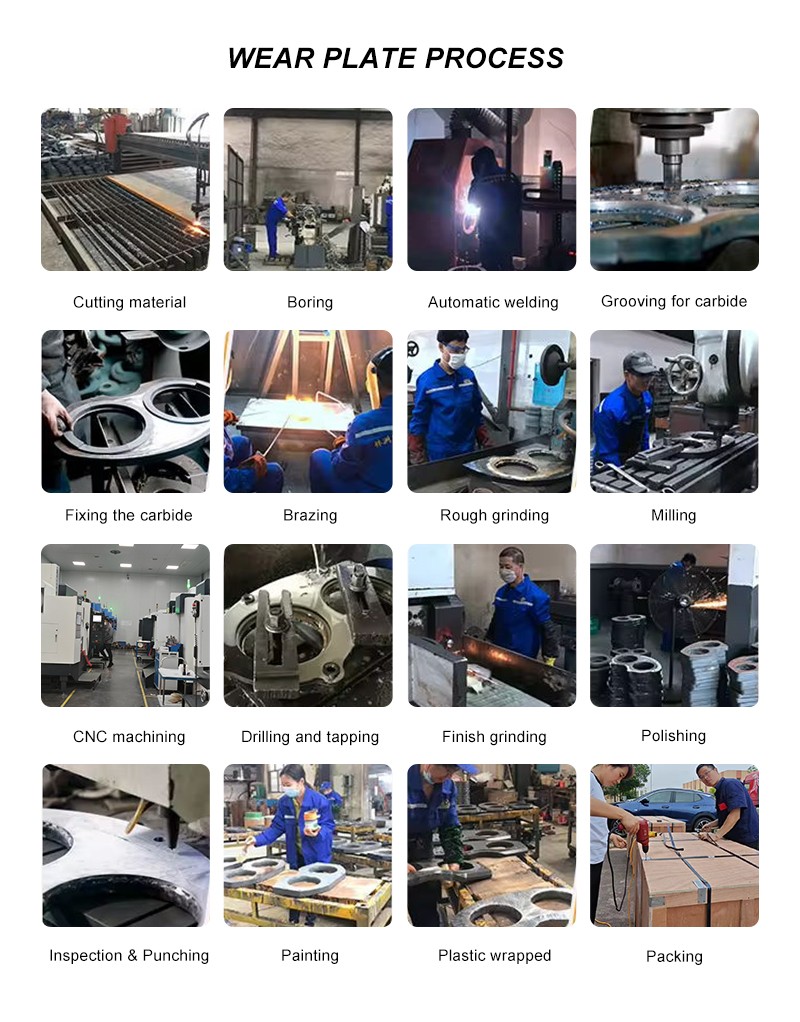

Production process:

The Role of Jinxin High Quality Carbide Plate:

1. Ensure correct position.

There is a cutting effect on the aggregate between the cutting ring and the wear plate of the concrete pump truck, so as to ensure that the cutting ring and the wear plate are correctly in place.

2. Improve the sealing.

Because there is a rubber compression ring between the cutting ring and the S valve it plays a cutting ring to wear plate a pre-pressure, so as to improve the sealing between the cutting ring and the wear plate.

3. Reduce the cost of use.

It will be the S valve inlet and cylinder outlet wear replaced by the wear between wear plate and the cutting ring. Thus the cost of replacing a set of wear plate and cutting ring is much lower than the cost of replacing S valve and material cylinder.

Packing and delivering:

About us: