Carbide ground rod for CNC cutting tools best factory price

Brand Name : JINXIN

Place of Origin : CHINA

Delivery Time : 7-14DAYS

Supply Ability : 1000000 PCS/MONTH

1. 100% virgin raw material 2. High wear resistance 3. Senior engineer professional technical service team 4. 100% inspection before shipment 5. Shipped on time

Tungsten carbide rod for cutting tools is a highly specialized material that is primarily used in industrial cutting applications due to its excellent hardness and wear resistance. Here are some key points about tungsten carbide rod for cutting tools:

Its main material is tungsten carbide (WC), a compound made of tungsten (W) and carbon (C) atoms. It is known for its extremely high hardness, close to diamond on the Mohs hardness scale. Tungsten carbide rods have high strength, toughness, and thermal conductivity. They are wear-resistant and can withstand high temperatures and abrasive forces, making them ideal for cutting, drilling, and machining applications.

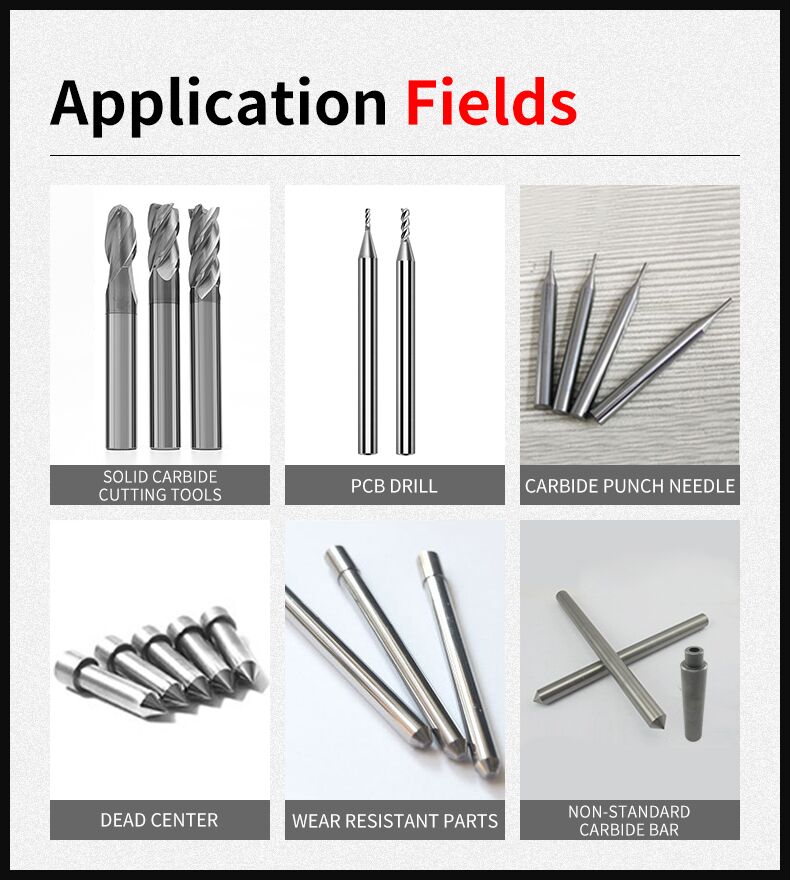

These rods are often used to make cutting tools such as drills, end mills, inserts, and other types of cutting tools. They are essential in industries such as metalworking, woodworking, mining, and construction where precision cutting and durability are critical.

Tungsten carbide rods may include features such as coolant holes for efficient cooling during cutting operations, which helps to extend tool life and maintain cutting performance.

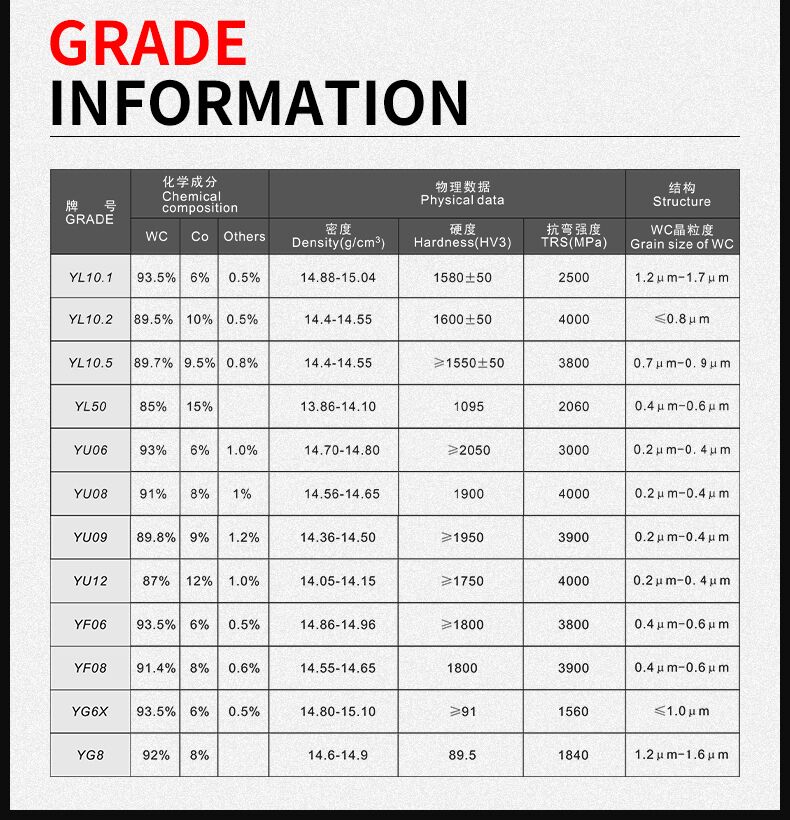

They are available in a variety of shapes, sizes, and grades to meet different cutting requirements and machine specifications. The choice of grade depends on factors such as the type of material being cut, the cutting conditions (speed, feed rate) and the required tool life.

Contact:vincent

Mob: +8613357331966

wechat:13357331966

WhatsApp: +8613357331966

Email: jinxin012@ojinxin.com