API 11AX V11-106 Valve Ball and Valve Seat

Brand Name : JINXIN

Place of Origin : CHINA

Delivery Time : 7-15DAYS

Supply Ability : 10 ton/month

Matierial : Tungsten carbide,tungsten

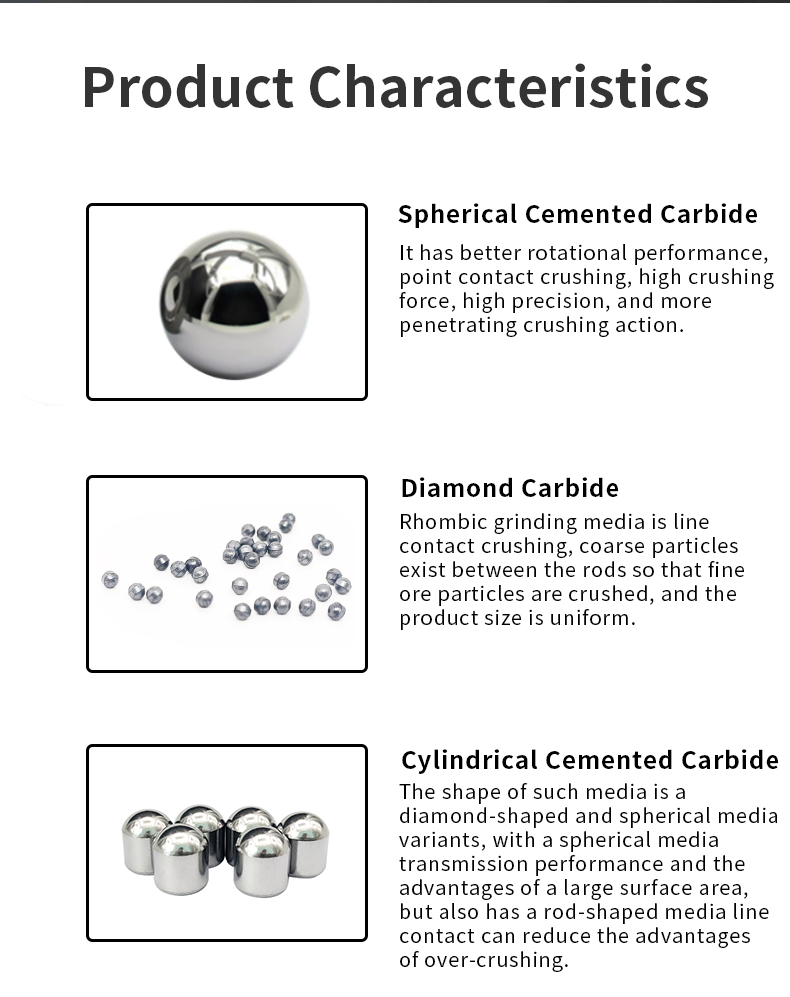

Cemented carbide valve ball or cemented carbide ball valve is evolved from the traditional plug valve. Its opening and closing parts are a ball, and the purpose of opening and closing is realized by the ball around the axis of the valve rod. The hard alloy valve seat is used in various specifications and configurations, and can be used under wearing, corrosive and corrosive conditions. Alloy valve seat is matched with alloy ball.

3. Each ball-and-seat combination is vacuum tested to ensure a perfect seal is obtained in all positions of contact.

High precision, high hardness, wear resistance, corrosion resistance, bending resistance, and harsh environment can replace steel balls.

| Tungsten carbide balls | |||||||||

| Type | Q-2.3 | Q-2.5 | Q-2.7 | Q-3.3 | Q-4.2 | Q-5.5 | Q-6 | Q-8 | Q-10 |

| Diameter | 2.3 | 2.5 | 2.7 | 3.3 | 4.2 | 5.5 | 6 | 8 | 10 |

| Tolerance (mm) | ±0.3 | ±0.3 | ±0.4 | ±0.4 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 |

| Type | Q-12 | Q-20 | Q-25 | Q-30 | Q-35 | Q-40 | Q-45 | Q-50 | Q-60 |

| Diameter | 12 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

| Tolerance (mm) | ±0.6 | ±0.6 | ±0.6 | ±1.0 | ±1.0 | ±1.2 | ±1.2 | ±1.6 | ±1.6 |

1. material : WC 94%, Co 6%

We can also provide other material as your request. Such as: WC 92%, Co 8%; WCNi

2. features :

high hardness , high precision , high antirust capability, high wear-resistant capability.

3. Application:

grinding, hardness examine machine, avigation , grinding machine, head pressure, and so on.

Any interested items please feel free to contact:

Contact:vincent

Mob: +8613357331966

wechat:13357331966

WhatsApp: +8613357331966

Email: jinxin012@ojinxin.com